The center’s work covers the full innovation cycle: from breakthrough research to development and marketing of high-tech solutions. In order to achieve that, the new facility builds on the university’s academic competencies and Gazprom Neft’s product-based approach to collaborate in the following fields:

- Sensor-based monitoring and quality control in the oil industry;

- New materials (ultrastrong metals and polymer compounds);

- Robots for various applications, such as geological surveys or pipeline monitoring all over the country.

- Automation of complex or hazardous tasks in oil extraction and processing.

“At the center, we engage in the full innovation cycle – from identifying demand to actual development and implementation of new technologies. With this approach, we can solve applied tasks and develop brand-new products. This collaboration with ITMO University is a priority for our company because together we are training a new generation of developers, engineers, and researchers who can create great startups and make daring ideas a reality,” says Alexander Sudakov, the head of the digital R&D program at Gazprom Neft.

Alexander Sudakov. Photo courtesy of Gazprom Neft’s press office

Read also:

ITMO’s Advanced Engineering School Named Best in Russia

Workflow at the center

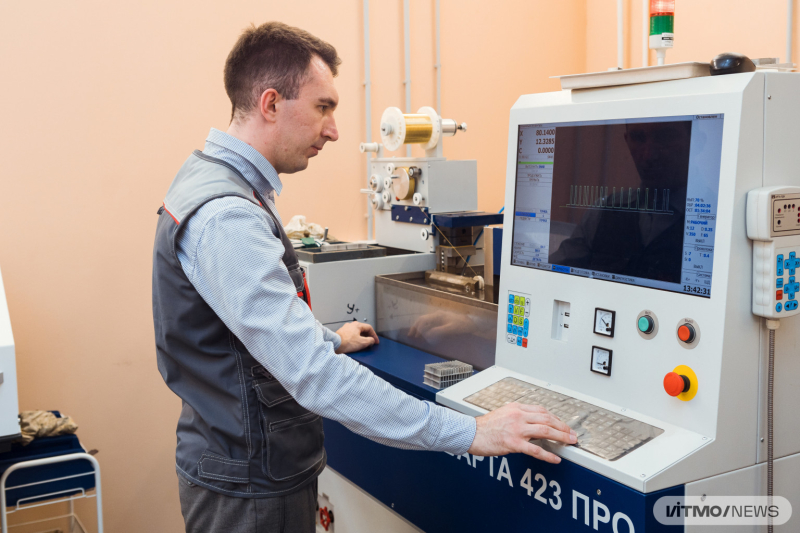

Every project is developed with the equipment of Gazprom Neft’s technology cluster and the university’s departments by experts and researchers from both partners.

Importantly, ITMO students can also join the ongoing industrial development, says Dmitry Bauman, the deputy head of the center. As of today, 18 students of various degree levels have made their contributions, learning to use the product-based approach and gaining useful engineering experience.

“There is currently a demand for industrial engineers on the market – and we are offering various ways to meet it. For instance, students at ITMO receive training at the Advanced Engineering School and specialized engineering educational programs, while our Innovative Industrial Center serves as a great platform for them to apply their skills within full-cycle innovation projects. At the same time, students learn product-based approach, which will allow them to have no adaptation time at their future workplace,” adds Dmitry Bauman.

Dmitry Bauman, the deputy head of the Innovative Industrial Center. Photo by Dmitry Grigoryev / ITMO.NEWS

At the start of any project, its team – comprised of experts from the center and Gazprom Neft – sits down to discuss the problems they need to provide solutions to, the materials they will use, the skill set they will require, and the time at their disposal.

When it comes to commercializing a solution, the experts from ITMO’s Technology Transfer Center, who are actively involved in the work of the Innovative Industrial Center, come to the rescue: they help conduct market analysis and patent search, as well as assist in IP-related matters.

At the center, development of all new devices and products is divided into several phases:

- Assembling a team. Each team includes Bachelor’s, Master’s, and PhD students. They are supervised by senior researchers who have prior experience leading similar teams, for example, lead engineers and heads of laboratories or administrative departments.

- Setting up a kick-off meeting between the team from ITMO and the staff from Gazprom Neft. Once a team is assembled, its members meet with company representatives to coordinate their work. There, they assign tasks, organize the workflow, and plan out the development process. After the first meeting, the team gathers once a week in order to keep the development on track.

- Developing the product, which is also divided into three stages. The first includes formulating a problem and then coming up with various technological solutions. The second involves creating a prototype for preliminary trials while drafting up the relevant project documentation. In the third stage, the team comes together to finalize their prototype and put it through the last round of testing.

According to the developers, planning out their work in this much detail makes it easier to avoid blunders while creating a high-quality product that will prove to be useful to the company.

What the center is currently working on

At present, the innovative industrial center has four teams of 5-7 members, with each team focusing on developing a single product.

The center’s researchers are:

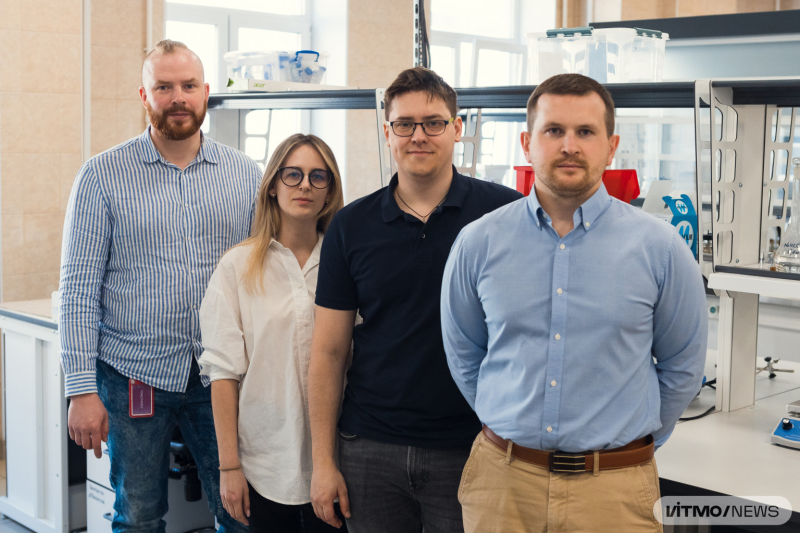

developing new sensors in order to identify contaminants in oil. The research team led by Ekaterina Skorb, the head of the Infochemistry Scientific Center, is working on an automatic microcoulometric analyzer that would identify the content of chloroorganic compounds in oil. Since such compounds corrode metals, this technology has the potential to extend the service life of oil extraction equipment.

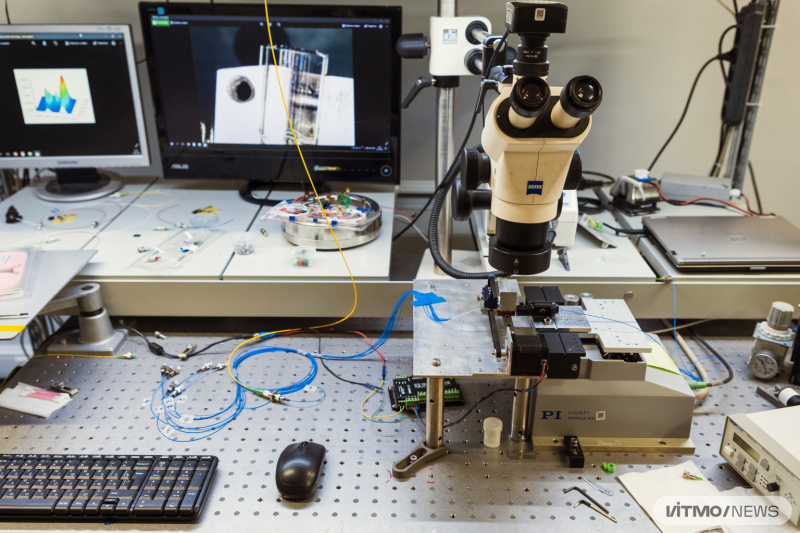

designing quality control devices for petrochemicals. This team is led by Andrei Kulikov, the head of the Higher School of Engineering and Technology. The scientists suggest creating an industrial Fourier-transform spectrometer which would function in the near infrared part of the electromagnetic spectrum. Such a device could help accurately measure a number of properties of light oil products (a class of refined oil products that are less dense than their counterparts and are used as fuels, e.g., gasoline, jet fuel, heating oil – Ed.), such as their aromatics contents, flash points, and octane and cetane ratings. Thanks to this technology, employees of Gazprom Neft will be able to monitor the quality of their products in real time.

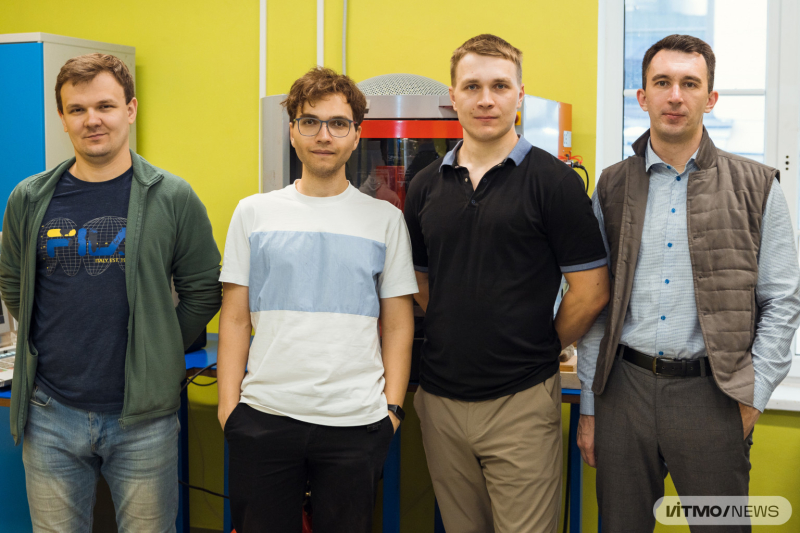

automating hazardous industrial processes, such as loading and unloading pipes for transportation. The team led by Sergey Kolyubin, a professor at the Faculty of Control Systems and Robotics, and Evgeny Khomutov, an engineer at the same faculty, is developing a robotic crane with a specialized clasp designed to lift large pipes. This device, which is expected to be twice as fast as those currently on the market, will require just one operator, instead of an entire crew.

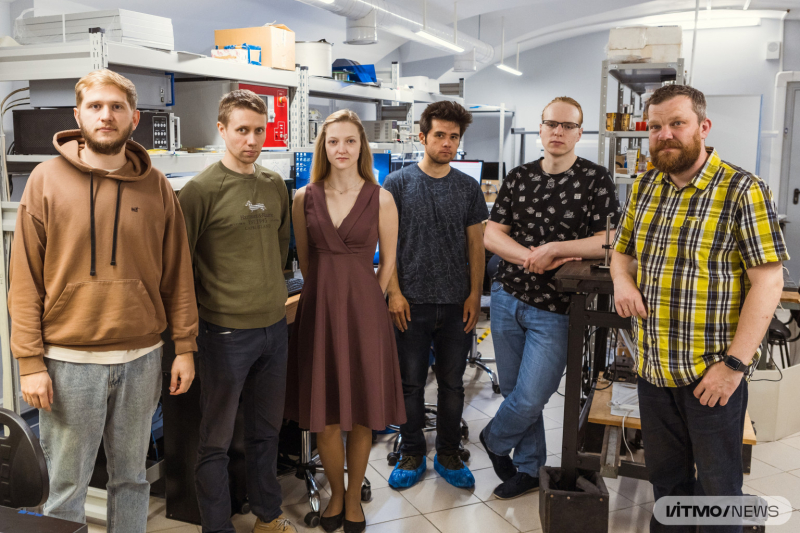

creating a new way to assess the quality of engine oils. The concept belongs to the team led by Ivan Polukhin, a researcher at ITMO’s Institute of Advanced Data Transfer Systems. This portable device will be able to determine the viscosity, density, conductivity, and temperature of engine oil, with the results being stored on a server. This means that specialists will be able to analyze samples remotely, with the integrated mathematical model predicting and then notifying specialistswhen to change the oil.

What lies ahead

As per Dmitry Bauman, the amount of partnership opportunities will increase in the future. That is why the center plans to implement a unified information system in order to better manage all of its teams and projects. This will make the center’s work more organized, with all of its employees having easy access to all the relevant information.

This industrial center is far from the first time that ITMO collaborated with Gazprom Neft. For instance, the center for high-tech chemistry, where university experts research prospecting, drilling, extracting, and transporting crude oil alongside scientists from the company, was opened in 2022. Another example would be the Research Center “Strong AI in Industry,” working on a decision support system for planning the development of deposits of natural resources.

Gazprom Neft is also involved in the creation of the Advanced Engineering School, which trains specialists in biotechnology, photonics, and cutting-edge sensors, as well as software engineering.

Egor Rakshin, a developer of a robotic crane, works on a model of the device. Photo by Dmitry Grigoryev / ITMO.NEWS