Carbon dots are a promising material for the production of LEDs and displays. They are non-toxic, biocompatible, and easy-to-manufacture nanoparticles made out of cheap ingredients, including citric acid and chlorophyll. Compared to perovskites, another type of materials that can be used in diode production, carbon dots are highly stable and can “survive” in many solvents, including water. Additionally, their surface can be functionalized by adding various groups and polymers, making the particles easily embeddable within the structure of other materials. All this makes carbon dots a convenient foundation for composites, such as light-emitting layers in LEDs.

However, at the moment carbon dots still cannot be mass-produced, primarily because of their low photoluminescence quantum yield – a parameter that corresponds to their brightness. Perovskites and quantum dots can boast a quantum yield of nearly 100%. With carbon dots, on the other hand, things are more complicated: in water (hydrophilic) carbon dots, the parameter rarely reaches over 60-70%, while in the more widely compatible amphiphilic ones (these can dissolve in polar and non-polar solvents, which is why they can be introduced into more polymer matrices) the photoluminescence quantum yield tends to be under 15-20%. These rates aren’t enough for the nanoparticles to be used in bright LEDs.

Read also:

Researchers Explain: All About Carbon Dots And Their Medical Applications

At ITMO, researchers have found a way to improve the optical properties of carbon dots by treating them to polyethylene glycol, a cheap and easily accessible polymer. In the process, its molecules act as an additional source of carbon that compensates for any nanoparticle defects and increases quantum yield without changing the structure, color, spectrum shape, or any other of their properties. To “cook” such nanoparticles for LEDs, the polyethylene glycol-treated carbon dots were “boiled” in a sealed autoclave in the oven for six hours. This hydrothermal method is most often used to manufacture carbon dots.

In their experiments, the team tested two types of carbon dots: hydrophilic ones (dissolved by polar solvents like water) and amphiphilic ones (dissolved by all solvents). The optical properties of hydrophilic dots benefited the most from the treatment: their maximal quantum yield was measured at 75-80%, whereas in the tested untreated ones it equals 30%.

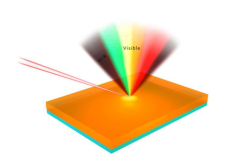

In amphiphilic dots suitable for LED production, the parameter rose from 20% to 25-30%. The maximal brightness of the LEDs based on treated amphiphilic dots reached 2,500 candelas per square meter (2,000 for the untreated dots), which is roughly comparable to the brightness of LEDs based on organic colorants and perovskites.

Moreover, the obtained LEDs proved to be more stable: they survived over 50 on/off cycles and 30 minutes of continuous operation without degrading, which is considered a good result.

Mikhail Miruschenko in the lab. Photo by Dmitry Grigoryev / ITMO.NEWS

“In the future, we are planning to increase the quantum yield even more: potentially, we’ll be able to change the structure of the LED for an improved charge transfer, as well as modify quantum dot synthesis. We are also working with other, charged, polar polymers for nanoparticle treatment; if applied, this method will allow us to control the dots’ ability to form films on various surfaces. We want to see how the materials will behave in this case – this can be beneficial in medical biovisualization, as well as in manufacturing of LEDs and screens,” says Mikhail Miruschenko, an engineer at the Center of Optical Information Technologies.