In developing the next generation of medical products, scientists synthesize and analyze large libraries of biologically active substances. The methods that are currently in use require each substance to be synthesized “in the flask” – or, in other words, in the macrovolume. This results in the production of multiple grams of each material, which is an excessive amount when it comes to analysis of biological activity. In addition, such a method takes up a lot of time, as reactions “in the flask” may go on for up to several days. Meanwhile, there may only be one suitable substance among a hundred.

The process of synthesis can be simplified through miniaturization and acceleration of chemical reactions. Today, this involves microfluidic devices and catalyzers, correspondingly. One promising method that could solve both challenges at once is microdroplet synthesis. Proposed relatively recently, it has yet to be implemented in practice.

In order to study the chemical reactions within a nanoliter droplet, researchers at ITMO have designed a microdroplet accelerator of chemical reactions. This lab set-up generates microdroplets via electrospraying, thus synthesizing a miniscule amount of the required substance and reducing unnecessary waste of reagents. Besides, synthesizing materials at a nanoliter volume makes it possible to accelerate reactions by millions of times – a feat not possible with catalyzers.

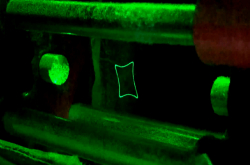

In order to conduct a reaction, researchers soak a paper cartridge in reaction mass and then conduct a strong current through it, initiating the spraying. Chemical synthesis occurs within the traversing droplets, which are then collected into special labware before further analysis.

Researchers have already tested their system on a reaction used to produce Schiff bases. Compared to conventional macrovolume synthesis methods, in which the reaction may take up to 30 hours, the new method resulted in a complete reaction within mere seconds.

“What makes our invention special is that it’s a simple and accessible solution. It doesn’t require any complex engineering, and it’s cheap to boot: all you need are wires, a source of direct current, and paper. We’ve already secured an investment from the Foundation for Assistance to Small Innovative Enterprises (FASIE) and won the intra-university grant competition ITMO Collab. My submission featuring this system also won in the stipend competition of the Sistema charitable foundation. Our end goal is to develop a versatile, simple platform for the acceleration and miniaturization of organic synthesis with the use of electrospraying,” tells us Maksim Semynin, one of the developers of the system and an engineer at ITMO’s International Research and Educational Center for Physics of Nanostructures.

Electrospraying. Footage courtesy of Maksim Semynin

At the moment, the researchers are planning to improve their control over the degree of acceleration and the product output. To that end, they plan to study the factors affecting the acceleration of chemical reactions within the microdroplet: the charge and size of the droplet and the concentration of chemical substances. They also plan to produce a prototype that can quickly conduct chemical reactions on an industrial scale, which would help quickly identify biologically active substances for the development of pharmaceutical products.

The project was conducted with support from the intra-university grant initiative ITMO Collab. It involves a team of researchers from the International Research and Educational Center for Physics of Nanostructures and is headed by Maksim Semynin, a Master’s student of the program Physics and Technology of Nanostructures.