In chemical research, scientists often have to repeat the same routine steps over and over — picking reagent solutions, mixing them, and tracking the reactions with different analytical methods. This kind of repetitive work can cause fatigue and human error. What’s more, optimizing experiments in the lab still depends a lot on a researcher’s intuition: to save time, they usually change only one parameter at a time.

Unlike humans, robotic arms never get tired or make random mistakes — they follow a programmed algorithm precisely. This makes it possible to optimize several parameters at once while planning an experiment. Robots can also work in conditions that are dangerous for people: for example, when the reagents or reaction products are toxic. In industry, traditional robotic systems are usually used for automation, but they’re costly, run on closed software, and can handle only a narrow set of tasks.

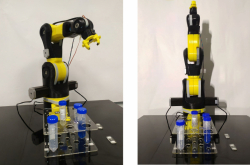

Researchers from ITMO University’s Infochemistry Scientific Center have come up with an affordable robotic arm for automation and studies of chemical reactions. It can be built from 3D-printed parts and runs on an open-source platform.

The robot can handle all the basic lab tasks: it unscrews test tube caps, mixes reagents in the right proportions, transfers samples between modules, and even places cuvettes into the spectrophotometer. To do this, it uses a robotic arm, a pipette dispenser, a USB camera, and a controller that processes what the camera sees. Its “brain” is a Python-based program developed by ITMO engineers to control the robot and analyze data.

Robotic platform for automation of chemical experiments. Photo courtesy of the research team

With the help of the robot, scientists automated an organic reaction — the condensation of barbituric acid with different aldehydes. This reaction could one day be used in biology to modify biomolecules. For that to happen, it needs to run fast in environments similar to those inside the human body. After running 45 experiments, the researchers managed to accelerate the reaction by more than threefold in a medium made of polyelectrolyte complexes. The team believes this new catalytic approach has a lot of potential in medicine — from imaging cancer cells and delivering drugs precisely to specific organs, to developing piezoelectric materials used in microelectronics, pressure sensors, and ultrasound devices.

In the future, the combination of affordable open-source robotics and 3D printing could make such systems commonplace and help scientists optimize chemical processes much faster.

Anton Muravev. Photo by Dmitry Grigoryev / ITMO NEWS

“We believe our robot can be used widely in both teaching and research labs. All you need are 3D-printed parts, and the control software can be written from scratch or taken from open-source projects. With such robotic platforms, we can automate tasks like the extraction of useful or toxic compounds and the search for new ways to speed up organic reactions. It would be especially exciting to use them to study more complex, multistage chemical processes,” explains Anton Muravev, an associate professor at ITMO University’s Infochemistry Scientific Center and one of the study’s lead authors.

Translated by Evgeniya Sotnikova