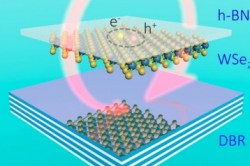

Today, optical fiber is widely used in communication. Many people know that it can transmit a signal over long distances with minimal losses, providing us, as an example, with stable and high-speed Internet. However, as devices become smaller and smaller, scientists and engineers have come up with an analog of fiber on a microscale. Such devices are called waveguides. They are integral in creating new-generation computers on an optical basis, serving to ensure efficient signal transmission and processing.

Most researchers now suggest complex and expensive technologies for creating waveguides, such as laser ablation or photolithography. These are time-consuming procedures requiring complex equipment, rare materials and additional sample processing. But scientists from ITMO University have developed an alternative method for creating optical micro-waveguides. It is based on a common inkjet technology.

Waveguide printing begins with the preparation of special ink. Its main ingredient is a suspended solution, or sol, of titanium dioxide nanoparticles. This material was chosen due to its high refractive index, which is necessary for the waveguide to effectively conduct the signal. In order to achieve suitable ink parameters, the scientists selected the right solvents, concentration of the main component, and surfactants. After that the ink is filled into an inkjet printer, which applies the material according to a given geometry on a clean glass substrate.

“The defining feature of our work is that we explained the choice of material, as well as the working wavelength and waveguide geometry, instead of just simply describing the properties and methods. Its main advantage, however, is that it offers a simple and cheap technique suitable for industry. This work was aimed at a practically applicable result since the very beginning, and now we have conducted the first industrial tests of our technology together with the IQDemy company. The results confirmed that the method can be upscaled without losing the waveguides quality,” comments Anastasiia Klestova, member of the SCAMT Laboratory of ITMO University.

It isn’t only the industrial adaptation of the waveguide inkjet printing technique that the scientists are currently focusing on. Their plans for the near future include applying inkjet printing in the production of other elements necessary for processing optical signal.

“It is obvious that the creation of elements of data storage and transmission based on the photons movement control is the fundamental technology for future computers. The most difficult part in the engineering of such devices is the development of efficient signal transport lines. But our solution removes all the major limitations in this area, and I have no doubt that soon we will see photon computing devices with waveguides created with our method,” notes Alexander Vinogradov, researcher at the SCAMT Laboratory of ITMO University.

Reference: Inkjet Printing of Optical Waveguides for Single‐Mode Operation. Anastasiia Klestova et al. Advanced Optical Materials. November 20, 2018