A total of 120 teams applied for the first cohort of the accelerator, with only 59 making it through the selection to join the program that featured three months’ worth of workshops, as well as meetings with mentors and potential clients. 22 diverse projects made it to the finals, some introducing new food products and services, others – technologies for eco-friendly food packaging, as well as novel solutions for agriculture. The new acceleration program is supported by the Ministry of Science and Higher Education within the federal project Platform of University Technology Entrepreneurship, its operator being the NTI Platform.

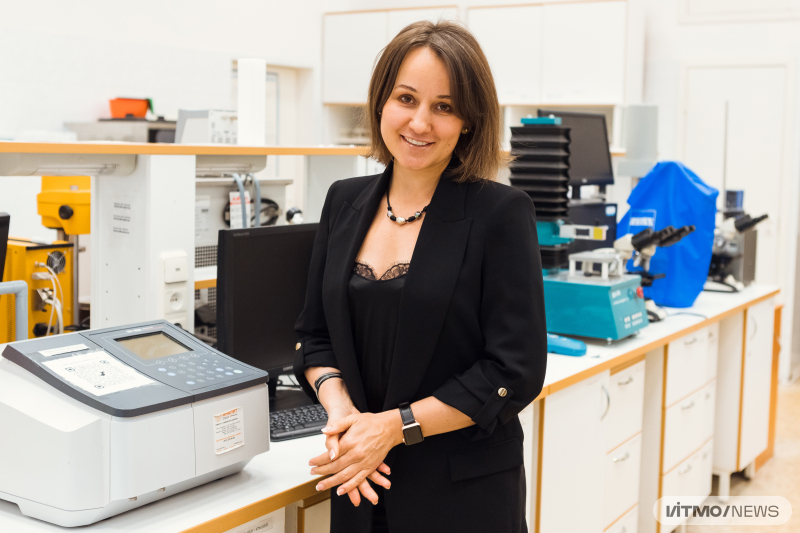

“Participating teams attended a variety of events, including personal consultations from our experts, business intensives, workshops, and others that are tailor-made for each team’s project. Moreover, this program is a chance for participants to package their projects ready for investments, find partners, and engage in some high-profile networking – and this is not all we offer. ITMO Accelerator is a wide-scale ecosystem for startups, working in collaboration with the university’s Technopark,” says head of ITMO Accelerator Alexey Solomatin.

Alexey Solomatin. Photo by ITMO.NEWS

At this Demo Day (the final presentation of projects), ten experts evaluated the finalists: Artem Ponomarev, CEO of Greenwise; Vladislav Libertsev, the head for development at Hood Street Food; Andrey Dyadyura, the head for development at Edelweiss; Tatiana Yanysheva, a brand strategist at Vkusvill; Dmitry Sobolkov, a project manager at Magnit’s Innovation Development Center; Anna Nenakhova, CEO of Uralchem Innovation; Olga Orlova, an associate professor at ITMO’s Faculty of Technological Management and Innovations; Rustam Kagirov, the head of innovation development at Lenta; Alexey Mikhalev, CEO of Sintez-Resurs; and Evgeny Babayev, the head of innovation search and selection projects at X5 Retail Group.

“Our main goal with ITMO’s foodtech accelerator was to help our teams find opportunities to grow their businesses. Foodtech startups are rather in demand these days because they hold the potential to solve an abundance of issues faced by the global community, including food safety, environmental protection, waste management, and more,” shares Alexey Solomatin.

Three projects were named best at the end of Demo Day: REzone, FastVIT, and DOnatural, all of which got the attention of the Innovation Development Center at the Lenta chain of grocery stores for the launch of joint pilot projects. Additionally, five projects were selected by IT company Automacon to be considered for investments: ScobyPlast, Lunarium Agro, МОРЕ рядом (Russian for SEA nearby), SVENIT, and DOnatural.

Participants of the Demo Day of the first foodtech accelerator. Photo by Dmitry Grigoryev, ITMO.NEWS

Eco-friendly fertilizer coating

The third place went to Bio-capsule, a biodegradable coating for granulated fertilizers. Some of the most common fertilizers are made with nitrogen. While this macroelement plays an important role in plant growth, a surplus of it contributes to water, soil, and air pollution. Therefore, one common mistake in agrochemistry is incorrect dosage of nitrogen-containing fertilizers. As a solution to this problem, the project’s team suggested a biodegradable coating that will cut down on nitrogen emissions into the atmosphere.

The novel encapsulated fertilizer will remain active longer than the conventional one, releasing nutrients gradually and thus producing a beneficial effect on plant growth. In numbers, the new product will allow farmers to cut down on fertilizer use by 15%, while increasing crop yield by 34% without the expenses of changing the soil. According to the team, their product will be of interest to greenhouses, flower and plant farms, as well as landscape designers.

“We have several more steps to cover, including approving the exact components of Bio-capsule and developing a working prototype to test its efficiency and specified properties. Some of the leading fertilizer manufacturers in the country have already confirmed the relevancy of our solution. Thanks to this acceleration program we had the chance to communicate with our prospective clients and partners, as well as learn to create value propositions and project development plans, from an idea to its implementation,” says Viktoria Sivukhina, the head of the project.

Hydrogel for soil

Agriculture faces other problems besides soil contamination. For example, 18.2% of all arable land in Russia consists of strongly alkaline soils, which make it harder for plant roots to absorb nutrients. Such soils are not suitable for most crops, leaving huge swaths of land effectively useless in terms of farming. Alkaline soils often also contain sand which filters water through itself deep into the ground, with very little of it retained by plants.

The Lunarium Agro project, which placed second in the foodtech accelerator competition, is dedicated to solving this issue. The team behind it came up with an idea of a biodegradable hydrogel that retains water while releasing nutrients like a slow-acting fertilizer, simultaneously improving the soil’s pH. By soaking up water, the hydrogel will keep the roots from having to burrow deep underground so that the plant’s energy is saved up to be transferred to its seeds. The startup’s founders hope to patent the name, logo, and chemical formula of their product. The team envisions both small local farms and major agricultural businesses among their future clients.

“We are currently working on a prototype and looking to expand our technical team in order to start experimenting with samples. Our plan is to finish developing and start synthesizing the hydrogel, then acquire certification through testing, and then launch our product on the markets of Russia and Central Asia. What makes us different from the competition is that our solution is multifaceted: the fertilizer is integrated with the hydrogel, so there is no need to introduce them separately. This way we both retain water and enrich the soil. That makes our product suitable for regions with severe desertification and soil degradation,” said Polina Komarova, the project’s co-founder.

Participants of the Demo Day of the first foodtech accelerator. Image courtesy of ITMO Accelerator

Fungi for recycling

At this time, the question of waste disposal is one of the most pressing for many businesses. Companies have to pass government inspections, pay environmental taxes, all while consumers demand more environmentally-friendly policies. Meanwhile, waste storage, disposal, and associated labor costs lead to significant expenditures.

The SPAWN project offers companies that generate various cellulose-containing waste to not only recycle it, but make a profit by using it to manufacture products. The idea is to recycle the waste by using particular strains of fungi, placing the mixture of these fungi and waste into the mold of a future product for no more than five days. Materials produced in this manner can be used to make furniture, packaging, construction materials, and other wares. The team behind the project claims that the SPAWN technology is capable of recycling receipts, cigarette butts, cartons, disposable tableware and everything else that contains paper and pollutants.

The project is targeted towards three types of clients in the B2B segment: factories that produce harmful waste, third place chains (banks, restaurants, hotels, and other places where consumers themselves create waste), and recycling plants that are looking to diversify. The creators are hoping to make profit through integrating their solution into individual operations and selling the license to produce this technology along with their unique fungi species.

“Right now we are at the fifth level of technology readiness (abbreviated as TRL; TRL 9 is when a product is ready to launch – Ed.), having created MVP (minimum viable product) versions of our materials, opened an independent laboratory as well as partnered with L'Etoile and Vkusvill to launch two trial projects. We plan to generate our first sales by June 2023,” says Daria Tokareva, the project’s creator and CEO.

New products for the industry

Some of the participating teams have also presented food products based on pea protein isolate developed for Uralchem Innovation. Namely, the invited experts tried and evaluated three recipes: a fermented yogurt substitute, a pastry, and sausages.

“We are among the active contributors to the plant-based protein market, striving not only to offer our own innovative solutions in pea processing, but also to support businesses that contribute pea protein isolate-based recipes. I believe that, guided by experts, students have accomplished some great results and we will definitely apply their suggested solutions,” shared Anna Nenakhova, CEO of Uralchem Innovation.