Path in science

I’ve been into science since childhood. My parents would buy for me these children’s popular-mechanics magazines with titles like Young Technologist and Modelmaker-Engineer. From them, I’d learn how the universe is set up, look at the pictures, and dream of becoming an inventor. I would also make cardboard models of various machines by copying schematics from magazines, studying the assembly instructions, and then painting it by hand to make it look real. I even made my own models based on my own schematics.

Starting from seventh grade, I began to take part in physics competitions and win prizes. At one such contest, I was awarded the necessary points to enroll at the St. Petersburg State Electrotechnical University (LETI). There, I began to study microelectronics. It was interesting to learn how the various microcircuits are made, how scientists pick materials that won’t overheat, and what microprocessors, resistors, transistors, and other such products actually do. During my studies at LETI, I mastered solid-state physics, chemistry (including physical chemistry), and materials science. As a result, I graduated as an industrial engineer in the field of microelectronics.

After graduation, I got a job at the Institute of Silicate Chemistry of the Russian Academy of Sciences (RAS). I went through almost all of the positions there – from engineer to senior researcher. For instance, I worked on a fundamental study on solid-state gas sensors: my job was to improve the performance of a lambda sensor – an oxygen detector that can be found in nearly every automobile. It gauges the proportion of oxygen in the exhaust, which allows us to reduce the amount of harmful emissions and fuel consumption. Such devices are based on zirconium dioxide, but I was trying to modify this material by adding various doping agents.

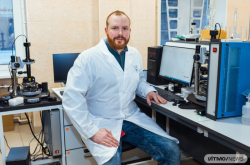

Maxim Arsentev. Photo by Dmitry Grigoryev / ITMO.NEWS

On working in Italy and returning to Russia

After about 15 years at the institute, I decided to try something new and join a postdoc program in Italy. There, I was able to contribute to two different projects. In the first one, I made computations for organic molecule-based photochemical converters – they were used to turn solar power into electricity. Such materials can be used to create organic solar cells. The second project dealt with molecular magnets, which can be used to develop ultra-high capacity data storage devices.

Having spent a year in Italy, I decided to return to Russia because I now had a child. I also decided to continue working in science – this time at ITMO, where I joined the ITMO Fellowship program. I heard about it from a former colleague, with whom I’d worked at the Institute of Silicate Chemistry. I liked how it sounded and, without much deliberation, submitted an application.

The foremost thing I like about ITMO is the atmosphere. Here, experts with competencies from all sorts of scientific fields come together to conduct research and help one another. In general, the environment at ITMO is very friendly and comfortable. If I want to work on a new project, I know that my superiors will always support me and that I’ll have access to lab equipment.

Read also:

ITMO Fellowship: ITMO Launches New Postdoc Track for Young Scientists Across Russia

From Reindeer Herders to Treating Diseases: Bioinformatician Anna Popenko on Studying Gut Microbiome

ITMO is also the place where I can implement my dream project. As a kid, I wasn’t interested just in physics, but in programming, too. But I never became a programmer – when I first applied to university and had to choose a major, computers were very expensive, so I didn’t have the chance to practice. With time, as computers became more affordable, I began to familiarize myself with specialized software on my own. It helped me perform computations and make models for my research into physical chemistry and quantum technologies.

I also see that a lot of work is being done at ITMO in the field of artificial intelligence and machine learning, and there are many IT professionals studying and working here. And so, it seems to me that it’d be a good idea to combine their work with my expertise in physical chemistry and multiscale modeling to conduct research together.

Maxim Arsentev. Photo by Dmitry Grigoryev / ITMO.NEWS

Perfect building blocks for 3D printing of the future

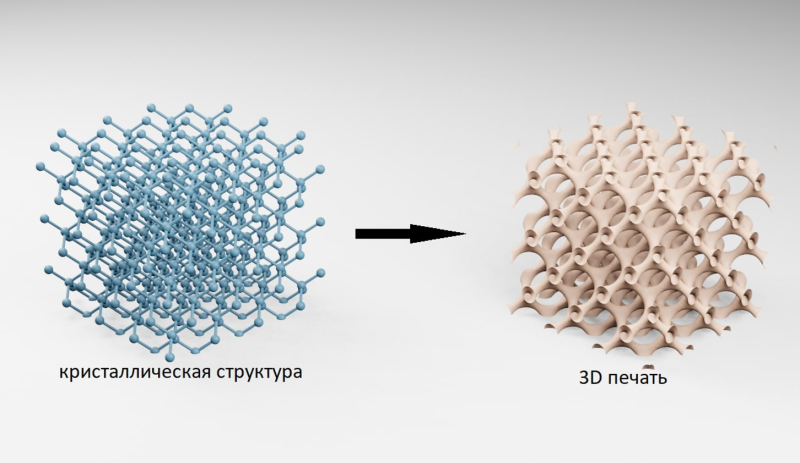

I am currently working on several projects at ITMO. One of them is about new materials for 3D printing. These days, you can 3D-print all sorts of things from aluminum, other metals, and plastic – even houses and cars. To do this, we use special software to convert a 3D model into code for the printer. This code is used to make a prototype. That’s what our team is busy with at ITMO’s Infochemistry Scientific Center – together with their research team, we are developing a crystal-like design for cell scaffolds filled with graded gels.

Printed products are cheaper and lighter than those made from conventional materials. However, there are caveats. The durability and energy absorption of a 3D-printed object depends on the building blocks it’s made from. Currently, hexagon-shaped structures are the most widely used in the industry. They are characterized by high energy absorption and durability, but unfortunately also have low anisotropy – this means that if pressure is applied in an unsuitable direction, the structures will collapse, making the whole printed object crumble.

Cristal-like design of scaffolds. Left: crystal structure, right: 3D printing. Image courtesy of Maxim Arsentev

In order to make 3D products more durable, we need to select a material with outstanding physical properties and create a new design for the “building blocks.” This is the hardest part of my job: many research groups from all over the world are working in this field and each has to come up with a remarkable idea to draw attention to their solution. After all, you can find a specific cell shape for each application. This is a constantly developing process, with researchers producing more and more shapes and approaches.

In one of my papers, I used the ATLAS database with over 10 million potential and existing crystal structures of zeolites – minerals that can be used as building blocks in printing. With a special high-efficiency approach, I selected 39,000 cube-like structures from ATLAS, described their topology (location and connections between atoms in space), and calculated their electron density. All of these parameters have an effect on a building block’s mechanical properties, including Young’s and shear moduli.

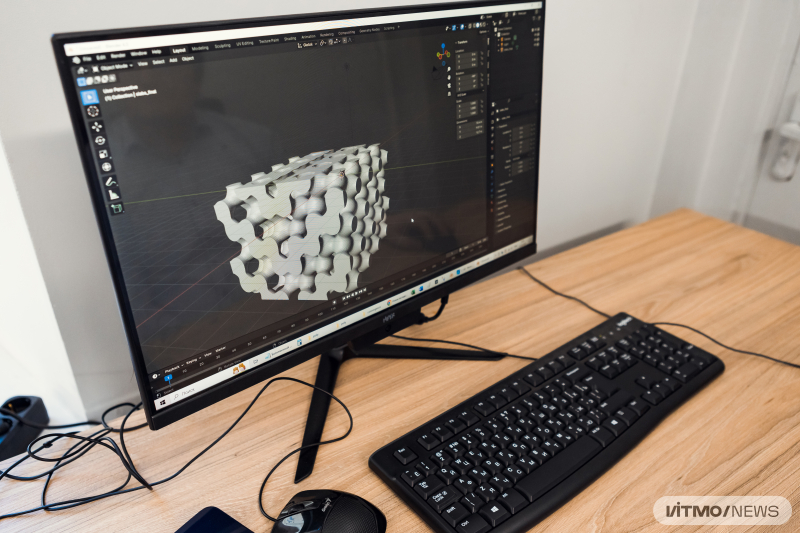

Using computer modeling, I have assembled a 3D model of a product from these blocks, predicted its properties, and verified my calculations by printing and testing it. There are many testing methods, but the most important ones are experimental tests with static and dynamic pressure – they help confirm a product’s properties in practice. I am planning to use several approaches: one of them is based on searching for cell shapes with optimal properties, while the other is about increasing durability with functional gels inside the cells. I am currently working on the latter. By the way, the resulting products are kind of similar to freshly baked bread: they bend under pressure but quickly restore their shape.

3D visualization. Photo by Dmitry Grigoryev / ITMO.NEWS

Dream project

In the future, I want to venture into other projects and create software that will identify new materials for use in power cells, calculating and predicting their properties. This is where the synergy between IT and chemistry can come in handy.

Lithium, which is currently the most popular material for power cells, is expensive. That’s why everyone is interested in finding a cheaper but equally efficient substitute. A conventional approach to this task would be to first develop a new approach by analyzing many research papers and factors that affect power cell properties – operational voltage, fire safety, power, capacity, and so on.

All of these routine tasks can be done faster with AI. For instance, one could write a parser and improve the existing IT tools based on their drawbacks. This way, it would be possible to extract information from scientific papers in order to assemble a database to be used as a basis for a model, complete with predictions and calculations. With all this, it is important to have both a great idea and a deep understanding of processes going on inside materials. If all goes well, you’ll have an IT assistant that will provide information on the types and ratio of materials for a power cell with specific properties; then, scientists will merely need to assemble and test the device. To make this project possible, programmers, materials scientists, electrochemists, and solid-state physicists will have to work together. Luckily, there are many such specialists at ITMO and in St. Petersburg, so this project may well become a reality.