The afterlife of a battery

Because of their various toxic components (lithium, zinc, nickel, cobalt, etc.) single-use batteries have to be properly recycled – usually they are collected at special recycling points. There, all the remaining useful parts, such as nonferrous metals and their salts, are extracted to be used again. For instance, manganese dioxide becomes a pigment for concrete and bricks, while zinc dust is responsible for blue colors in fireworks.

Rechargeable batteries, on the other hand, can be used multiple times when charged with a special device. Such chargers are usually powered through a USB or a plug and are compatible with a limited number of battery types, for instance, AA, AAA, or nine-volt batteries. As this doesn’t account for much convenience, companies and researchers around the world are developing more user-friendly chargers. For example, in 2016 the American company Lightors came up with a special wireless charging device for its own AA and AAA batteries. However, what about other types of rechargeable batteries produced by other players on the market?

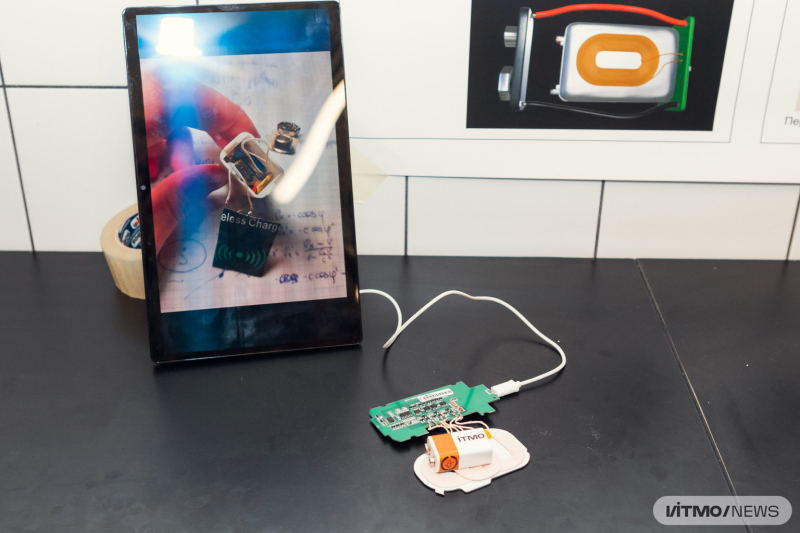

The prototype of the new device placed on a Qi-certified wireless charger. The white platform is a transmitter and the chip board is its power source. Photo by Dmitry Grigoryev / ITMO.NEWS

A new beginning

A team of students from the Wireless Technologies program of ITMO’s School of Physics and Engineering assembled a prototype of a nine-volt battery that can be recharged with any wireless charging device. The battery has two indicators: red – for when charging is in progress, and blue – for when it’s complete.

“What makes our device stand out is its compatibility with any wireless charger, such as that for a smartphone or smartwatch. It takes only 15 minutes to charge it to its full potential, 270 mAh, and it can be recharged up to 500 times,” says Andrey Mineev, a developer of the new device.

A nine-volt battery is more durable than an AA one, while also being compatible with a wide range of devices, from toys to dosimeters and receivers. What’s more, you can now recharge it without taking it out of the device it’s used in – you can just place the device itself on the charging station.

“Take a multimeter, for example: in order to change the battery there, you have to first take the device apart, remove the old battery, and insert the new one. This doesn’t sound very convenient. And if you use our battery, you can just place the multimeter on a wireless charging station and it will recharge just the way your smartphone does. It’s convenient and eco-friendly. We hope that our battery will find its demand on the market – so far, it doesn’t have any competition,” adds Danil Chernomorov, another developer.

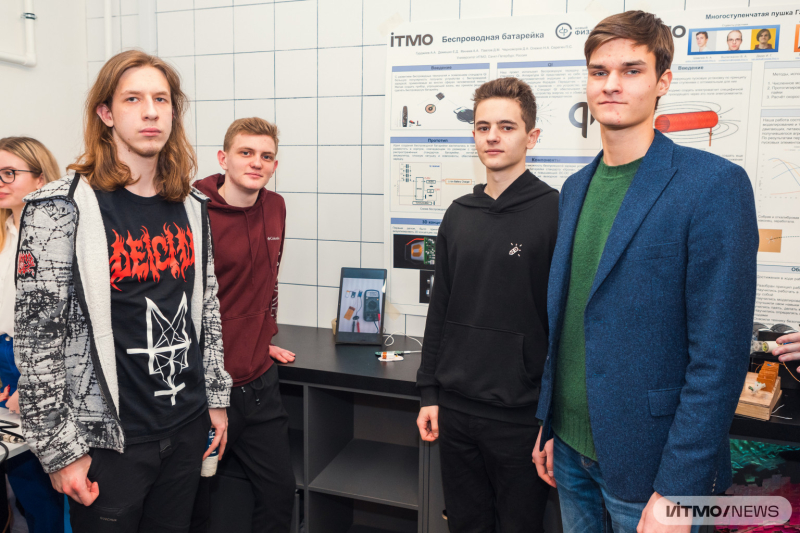

Project team left to right: Egor Demeshko, Alexander Gurdzhiev, Danil Chernomorov, and Andrey Mineev. Photo by Dmitry Grigoryev / ITMO.NEWS

Among the new battery’s strong points is also the affordability of its components: it’s made from cheap microchips available at any hardware store.

Read also:

New Generation of Wireless Chargers Developed at ITMO: Here’s How It Can Change Your Life

All About ITMO Researchers’ Latest Advances in Wireless Power Transfer

ITMO University Scientists Develop a Tool for Wireless Charging of Multiple Devices

First-years turned Elon Musks

The project’s team features first-year Bachelor’s students Alexander Gurdzhiev, Egor Demeshko, Andrey Mineev, Denis Pavlov, and Danil Chernomorov, supervised by Pavel Seregin and Nikita Olekhno, researchers at ITMO’s School of Physics and Engineering. Students could choose one from a list of topics suggested by the researchers, eventually settling on the idea for a wireless rechargeable nine-volt battery. According to the students, wireless devices represent a rapidly growing market.

In just a single semester, the team not only developed a prototype, but also presented it in front of a board of experts. Nikita Olekhno, who curates student projects at the Wireless Technologies program, is confident that in the future the team will be able to secure funding for their device if they submit it to the START or UMNIK contests.

“With such projects, we give our students the chance to see why they learn all of the complex math and physics. They came to the school to become engineers, to turn into the next Tesla or Musk, and in order to do that they will have to go through each step of the engineering process. First, you set a goal; then, you analyze the solutions available on the market; next, you develop your own idea, calculate its production costs, assemble a prototype, and compile the technical documents, including a user manual. It’s important that our students know which track to choose and what they plan to do in life before they graduate,” explains Mr. Olekhno.

Among the team’s future plans are doubling the battery’s capacity, which can be done with self-engineered smaller printed chips. In this case, students will be able to make another battery type, such as AA. The battery could also be turned more eco-friendly with a replaceable accumulator module – the only part of the device that would have to be replaced, its 3D-printed body and other electronic components being more durable.