In the late 1980s, scientists discovered that surface roughness leads to significantly increased osseointegration or, simply put, the survival of medical implants. Nowadays, researchers focus on the influence of the geometric structure of various surfaces on the behavior of living cells.

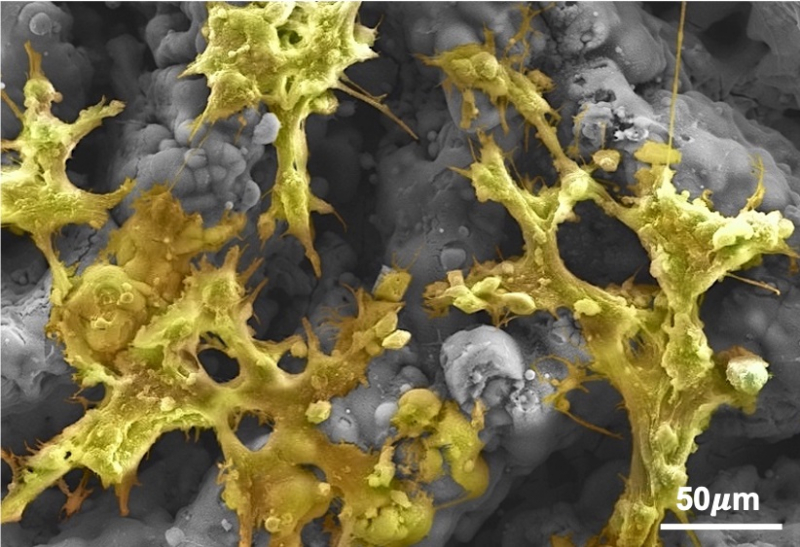

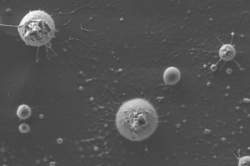

A research team from ITMO’s International Laboratory for Laser Micro- and Nanotechnologies has developed a laser method for forming micro- and nano-scale surface geometry of titanium-based dental implants to improve their compatibility with living cells. The method implies the use of lasers for creating a surface relief that mimics the structure of compact bone tissue. Now, the scientists are conducting in vitro research on stem cell biointegration on laser-modified surfaces. They have already managed to prove that the number and quality of processes, as well as the shape of cells and their ability to attach to the surface, depend on the period and depth of osteonic structures.

It is proposed that dental implants with a special micro-scale surface geometry will foster bone growth faster and more efficiently, thus increasing the success rates of dental implantation.

Reference: Veiko, V., Karlagina, Y., Itina, T., Kuznetsova, D., Elagin, V., Zagaynova, E., Chernenko, G., Egorova, E., Zernitskaia, C., Manokhin, S., Tokmacheva-Kolobova, A., & Odintsova, G. (2021). Laser-assisted fabrication and in vitro verification of functionalized surface for cells biointegration. Optics & Laser Technology, 138, 106871. https://doi.org/10.1016/j.optlastec.2020.106871