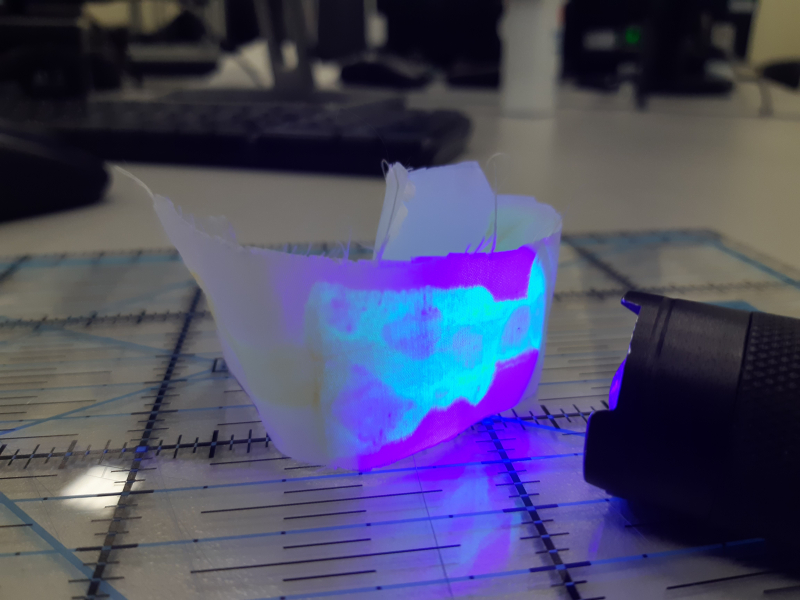

The crystallization is done as follows: a special solution of halide salts, polyethylene glycol, and other precursors is mixed in a specific way at a given temperature. Then, the solution is applied to polyester fiber (in this case, a white one). After that, the sample is heated so as to eliminate the solvent. As soon as the solvent evaporates, the crystals start to grow rapidly; this process ends in 2-3 hours and can be sped up if the textile is put in vacuum.

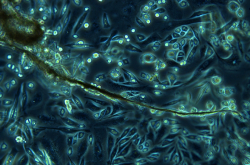

The image was made under UV lighting of a mercury lamp. The physical effect that lies at the basis here is photoluminescence. The textile absorbs UV light and re-emits it in the visual band. The images were made with the help of a microscope with a 10x magnification.

The work of ITMO’s Laboratory of Hybrid Nanophotonics and Optoelectronics (PeroLab) is conducted as part of the Russian Science Foundation grant (№19-73-30023) focusing on perovskite-based flexible optoelectronic devices: solar cells, light-emitting diodes, and multipurpose devices. The researchers believe that in the future, they will succeed in creating fabric-embedded diodes, and the samples above are a small step towards this goal.