The origins of FabLab

ITMO University FabLab is a small workshop where our university’s students and lecturers can create various components for their research or experiments. The idea of launching FabLab belongs to then-students Aleksei Shchekoldin and Evgeniy Anfimov.

Before FabLab, they developed their own creative DIY projects at home or at other universities. Then, they decided that it would be great to work on their ideas at ITMO. They came with this initiative to the university's Rector, who approved it.

At that time, Alexei and Evgeniy were in the final year of their Bachelor’s programs. By the time they became Master’s students, the FabLab opened its doors to anyone willing.

FabLab was launched in 2015 at ITMO University’s Technopark as part of Project 5-100, a national program that aims to increase the competitive ability of Russian universities on the global scale. The laboratory included computer stations and workplaces where the visitors could use various technical equipment.

ITMO students can come to the FabLab and use its equipment free of charge. Such an approach allows it to attract a great number of students and turn the workshop into the kind of coworking space where one can exchange experience and ideas as well as bring them to life.

FabLab’s purpose is to bring together people with projects of their own, help them develop their ideas, and maybe launch startups. It also offers workshops on working with various equipment, programming and the TRIZ (TIPS) approach to problem-solving.

Available equipment

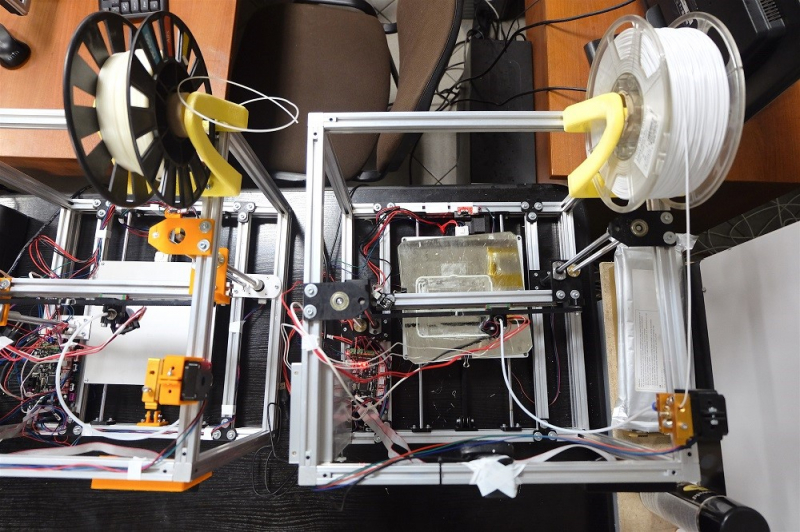

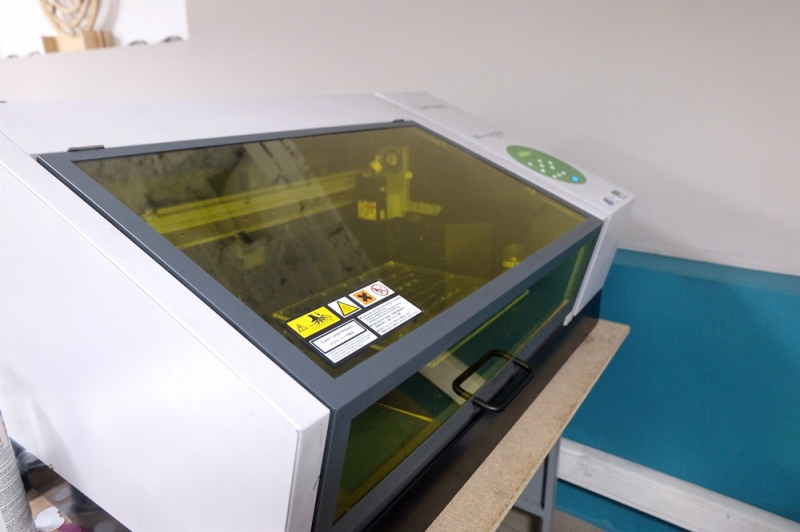

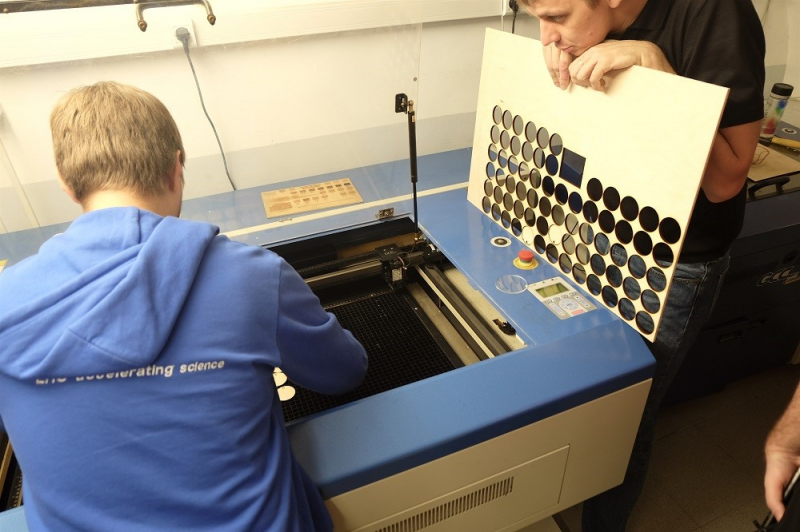

The university chose the equipment they bought for the laboratory based on a poll they took among the students. As a result, our FabLab is now equipped with MakerBot 3D printers, GCC laser engravers and a Roland MDX40 milling machine, as well as soldering stations. With time, the laboratory acquired even more tools, and you can now find almost any instrument there.

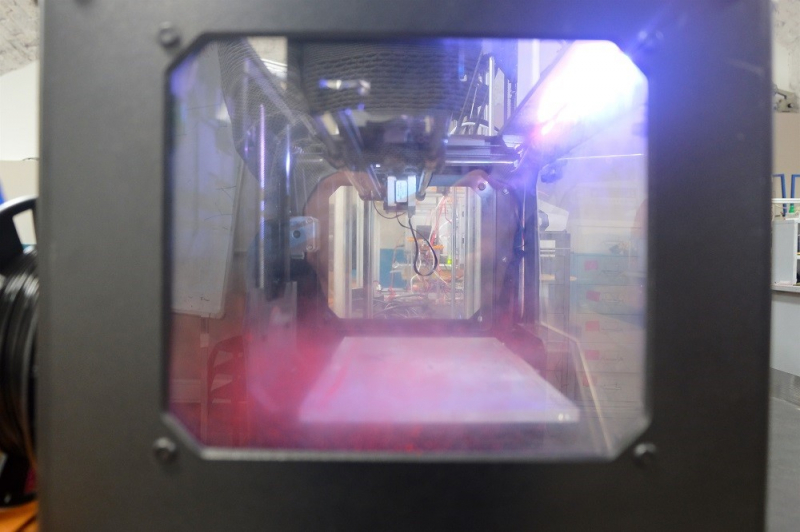

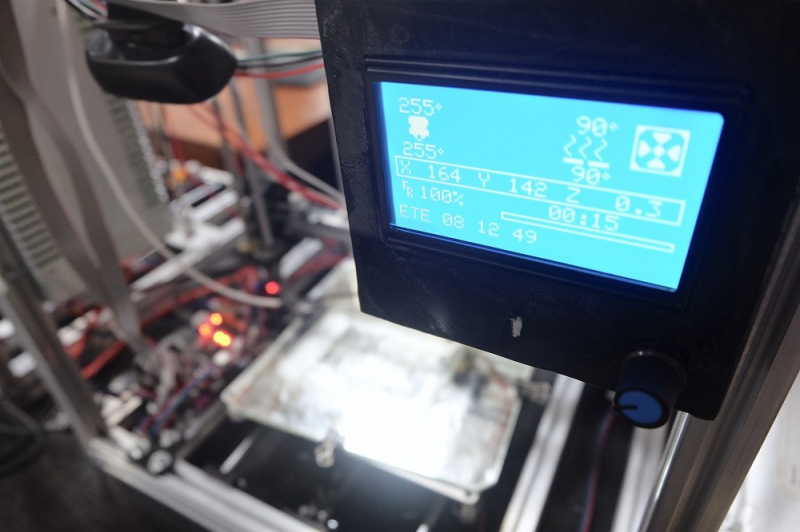

The laboratory even has printing devices assembled from DIY kits:

Many pieces of equipment are being upgraded by students. For example, the printers on the next photo were assembled from the RepRap kit, which is part of an initiative aimed at the creation of self-replicating devices.

The FabLab also has an UV printer and GCC Hybrid MG380 and GCC Spirit LS40 laser engravers, as well as various CNC milling machines.

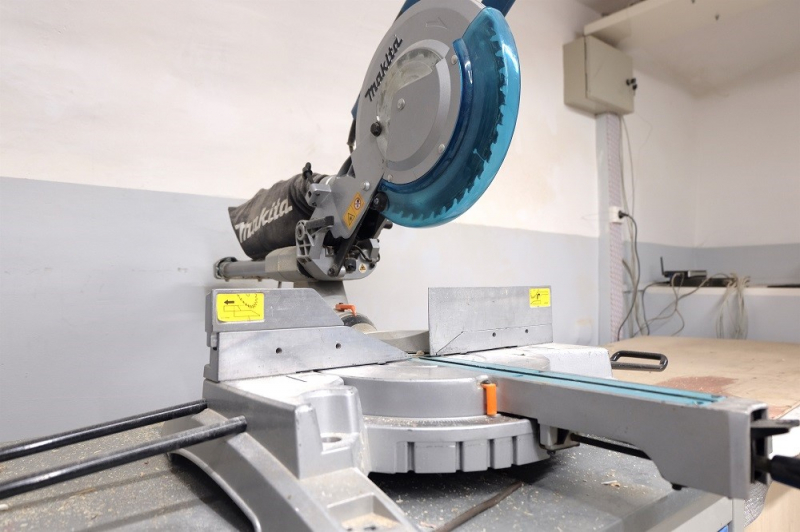

There’s also a drilling machine, a circular saw and various handheld tools, i.e. everything that a maker’s workshop has to have. We even have a wire for cutting polystyrene foam which is a huge help when modeling with this material.

The laboratory also has several PCs that can be used for sketching, 3D modeling and programming. At the present moment, there are over 30 different types of equipment at FabLab.

DIY

The students create 3D models, burn logos into wood and design art objects. At FabLab, everyone can work on their individual projects, for example print a figure of their favourite movie character, assemble a milling machine, a quadcopter or a designer guitar. The laboratory’s equipment offers an opportunity to bring one's ideas to life a lot faster than what making them at home would've taken, and with a higher level of precision.

FabLab’s “products” are regularly exhibited at various events. For example, 3D printed figures were demonstrated at the VK Fest last July. Then again, it is not just art objects and hobby projects that are created at the laboratory. The students also work on high-tech solutions.

In the first year of FabLab’s existence, the Evapolar portable A/C system was developed at the laboratory. The project launched an Indiegogo campaign to gather its target capital. Among other projects that were developed at FabLab are keyboards for the visually impaired and the FlashStep automatic decorative lighting system.

FlashStep was developed by the laboratory’s co-founder Evgeniy Anfimov. It is a system for lighting the stairs of multi-story country houses. The solution was monetized and is now popular among smart house owners.

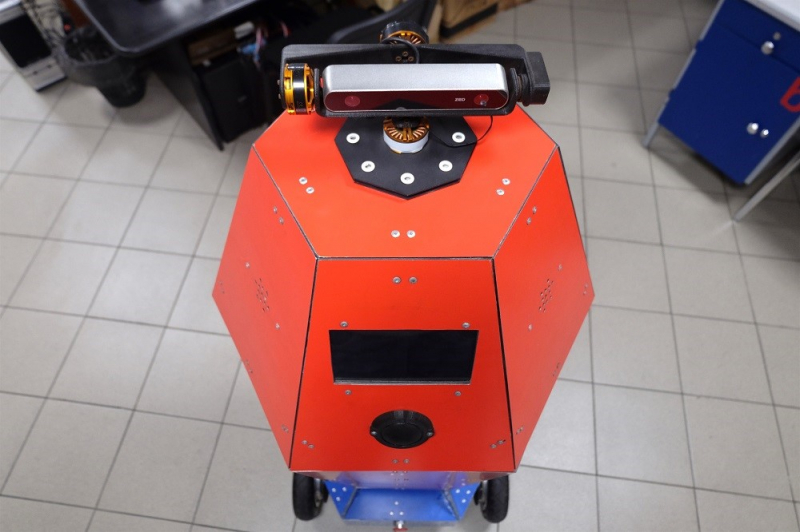

Another noteworthy project is the SMARR – a prototype robot that makes use of VR and AR technologies.

Its development, which was supervised by the laboratory’s co-founder and head Alexei Schekoldin, took two years. Ten ITMO students participated in this project. They received help from ITMO University lecturers, namely Sergei Kolyubin, an associate professor at the Computer Technologies and Control,who was the project’s research advisor.

SMARR can be controlled with the help of an Oculus Rift headset. Apart from an image from the robot’s camera, the user gets information (for example data charts) that’s produced with the help of AR technology. The robot can also navigate in unfamiliar places by using probabilistic methods to create maps.

In future, SMARR’s authors plan to sell the robot. One of its possible applications is working in hazardous conditions, for example on oil rigs. This will help decrease the risks for workers during assessment events. The developers also believe that their invention can be used in the tourist industry. People will be able to use the robot to go on virtual tours of major museums, for example.

Another startup that’s based at FabLab is 3dprinterforkids. Its founder Stanislav Pimenov teaches children 3D modeling and encourages their interest in robotics.

What’s next

In order to offer our students a wider range of instruments, we study the needs of our university’s other laboratories. At the same time, we have plans for turning FabLab into a small startup with a lean towards DIY. We also want to conduct more workshops and tours for school students, as well as practical sessions for adults.

You can stay up to date on the latest from ITMO’s FabLab on VK, Facebook, Telegram, and Instagram.

This article was originally published in ITMO University's Habr.com blog.