The technology is based on the infusion of metal nanoparticles into the plastic used to manufacture bottles. The addition makes it possible to apply images onto the preform using a pulsed laser.

ITMO.NEWS chatted to Ulyana about the new technology, the prospects of its integration, and its effects on the environmental aspects of plastic production and recycling.

Can you tell us what makes this invention so unique?

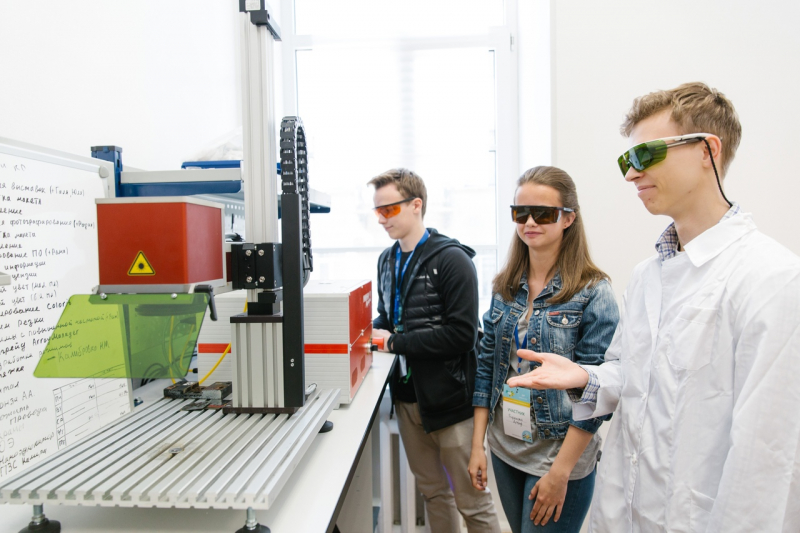

The technology is based on the introduction of metal nanoparticles into the polymer polyethylene terephthalate (PET) and then printing an image directly on the material. We used an ytterbium pulsed fiber laser with a 1.07 micron wavelength, to which PET is almost transparent. The color of the material is changed by way of heating the nanoparticles. The heat is transferred to the polymer matrix, resulting in the creation of pores due to the evaporation or degradation of PET. Thus, we’re able to form contrasting areas on the surface of the polymer.

What are the benefits of this method?

It’s a very promising technology from the environmental point of view. PET is one of the most popular packaging materials around, so it is improbable that we’ll stop using it in the near future. Fortunately, it can be recycled (on plastic bottles and other items, the material is marked with 1 or PET). Removal of labels is a notable issue when preparing PET waste for recycling. These labels are made from other materials, such as non-recyclable plastics, paper, or foil. They also utilize dyes and are attached with a layer of adhesive. Thanks to this new approach, it would be possible to eliminate this part of the recycling process.

Also, when we’re talking about bottles, another benefit is in applying the label image onto the preform which later expands during manufacturing, thus conserving resources. We’ve conducted experiments but will need to develop them further.

What was your sponsor’s interest: the environmental benefits, reduction in production costs, or resource efficiency?

The company that commissioned this project, APG Eastern Europe, has a patented technology called LaserPET. They were interested in honing the process of applying high-quality contrasting imagery onto the material, including such aspects as identifying the optimal additives and their volume, as well as improving the production rate and the quality of labels.

What was the result? Were your findings used in production?

The technology was partially integrated, but with a dye based on different materials instead of metal nanoparticles. Laser-etched packaging can already be found on store shelves.

My project, unfortunately, did not continue. But the results we’ve produced are included in my thesis and there is additional research planned; this will be described in an upcoming article I’m currently working on.

What’s most important for me is the experience I’ve acquired in talking to others, being in charge of a project, using various equipment, presenting my results, and so on.

Did you have a personal interest in the project?

I was interested in this because the subject of environmental issues like waste recycling is very timely right now, especially in Russia. To me, it was novel and unusual.

How do you plan to use your findings in the future? Will you keep trying to introduce it into production?

I’m very hopeful that I’ll find a company that’d be interested in conducting thorough and quality work on this topic. It’d be interesting to develop a whole “palette” of additives that differ in chemical make-up, ratio of additive to polymer, and the size and shape of nanoparticles. One pertinent task is to analyze the dependencies between these parameters in order to produce high-quality, defect-free, contrast-rich labeling. In my view, this has great potential for a number of publications, patents, projects, and so on.

There’s also the possibility of looking at other polymers aside from PET. But that’ll depend on the potential partner company.

When you started out as a student, what drew you to laser technologies?

It seemed to me like the most interesting subject out of all that are found at universities in St. Petersburg. At first, I applied for laser engineering, but didn’t have enough points, so I ended up here – and I believe I was very lucky. We’ve got a great team both in our student group and at the lab. This subject area is more practical. The emphasis here is not on the design aspects of laser and optical systems (although that’s still present), but on studying the effects of laser radiation on various materials. Because of this, students spend most of their time engaged in experiments, making the educational process more exciting.

What are your future plans? Do you want to stay at the university or go into the industry?

I’ve gotten my Bachelor’s now and just enrolled into a Master’s program. I hope that my career will continue both at university and in the industry. I’m still continuing work on the subject of my graduation thesis – the physical principles and possible applications of nanoparticle-based laser marking of transparent polymers. Right now I’m writing an article. I’d like to take on a project to serve as a constant source of employment; to develop a certain field, hopefully polymers. I can see myself as a specialist and I hope that is what’ll happen.