The method of inkjet printing with nanoparticles or organic materials has appeared relatively recently and is now actively developing. Among its potential applications are microelectronics and security printing to prevent forgery.

“Previously, people tended to use indirect methods for this. For example, a relief is etched on a piece of metal and then transferred to paper under pressure. However, this technology is very complicated and cannot be used on some surfaces. We found a way to print holograms directly, which is much easier,” says Kirill Keller, an employee of the SCAMT laboratory.

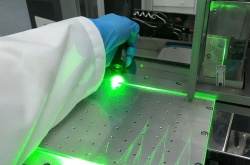

With direct printing, holograms can be put on paper, plastic or glass. This is possible due to specially developed ink and a controlled printing mechanism. The ink contains submicronic spheres which form into tightly-packed grids when they dry. Passing through them, the light refracts and, depending on the angle of incidence, reflects in different wavelengths. The grid order also determines the quality of the hologram and its daylight visibility.

“We were the first to use a mathematical approach to evaluate the orderliness of such structures during the printing process. Thus, it is possible to understand the way the substrate nature and temperature or the composition of the ink affect structural ordering. We control the entire process, starting with the creation of the ink: we optimize the viscosity, surface tension, density and boiling point. Then we come up with a pattern, fill the cartridge and start printing. We apply the ink with spheres to the substrate drop by drop, the solvent evaporates, and we monitor how the grid is formed from the spheres,” Kirill continues.

The researchers have developed three different ink mixtures to obtain full-color images with a holographic effect. These differ in the size of the spheres, which, in turn, affects the length of the reflected wave. Spheres are chosen so that they produce red, blue and green colors at almost the right angle. By combining these three mixtures, one can create a full-color holographic image. Controlling the printing parameters makes it possible to print unique holographic patterns directly on paper: for example, on banknotes and documents. This will provide an additional degree of protection, visible even in daylight.

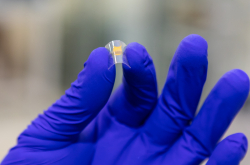

Vladislav Slabov handles another area of inkjet printing experiments. Within its framework, ITMO University together with the University of Aveiro in Portugal develops organic-based piezoelectric materials. Piezoelectric materials can transform an electrical signal into mechanical vibrations – and vice versa. They are often used in various automated systems or sensors. Organic piezo-elements are the most promising; for instance, ones based on diphenylalanine peptide. Its crystals have a good electromechanical response but are very difficult to grow. Scientists at ITMO University have decided to do this using inkjet printing technology.

“The main difficulty is that, for a strong response, the diphenylalanine crystals have to be strictly parallel to each other,” Vladislav says. “We developed an optimal ink mixture and optimized the printing conditions. Usually, when a drop of ink dries, diphenylalanine crystallizes the way it dries: from the edges to the center of the drop. We chose a pattern of simple lines for the crystals to grow in parallel. Eventually, when we sent the resulting structure for analysis to the University of Aveiro, it turned out that the response had actually increased. Our method proved to be effective.”

The scientists did not just develop a type of ink to print organic material; they also created a way to control the direction of crystal growth. Thus, this method can be adapted for different bases or substrates. Such printed structures can be used in various sensor devices.

“At the moment, this work is more theoretical and not fit for industrial use. But we hope that it brings us closer to applying these materials in various devices,” says Vladislav.

The undergraduates are going on an internship at the University of Aveiro in Portugal. While there, they will study the optical properties of new materials and the technology of industrial hologram production as well as develop devices based on diphenylalanine crystals.

The research is conducted with the support of the Russian Science Foundation.

Reference:

Inkjet Printing of Multi-Color Daylight Visible Opal Holography Kirill Keller et al.

Advanced Functional Materials, Apr. 10, 2018.

Diphenylalanine-Based Microribbons for Piezoelectric Applications via Inkjet Printing Sofia Safaryan, Vladislav Slabov et al.

Applied Materials and Interfaces, Mar, 2, 2018.

Translated by Pavel Vorobyev