According to Statista, 54% of respondents globally use smartphones for work-related purposes, such as answering emails and messages. In the process, they usually utilize on-screen keyboards; however, it is not the most convenient solution, especially in cases when users need to switch between apps when replying. That’s why companies such as Logitech, Lenovo, and others offer various external keyboards – foldable, chargeable, wired, or wireless.

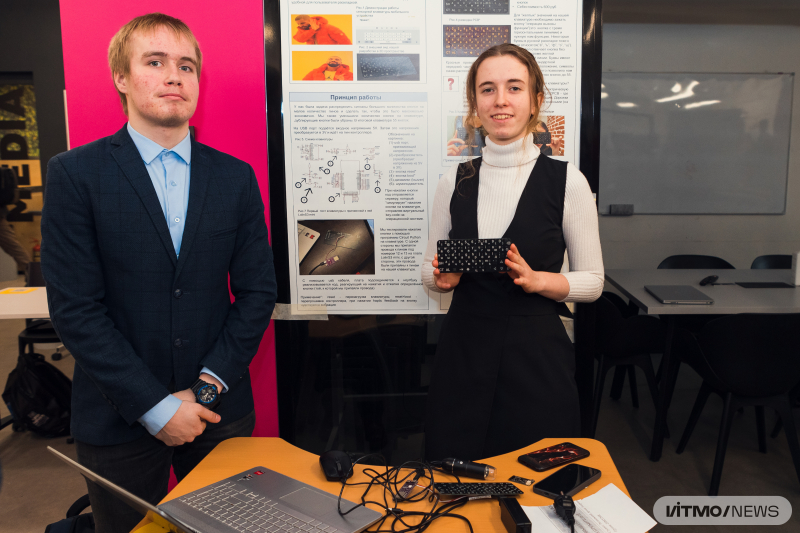

Elizaveta Lokun and Ivan Osetrov, first-year Bachelor’s students of ITMO’s School of Physics and Engineering, have recently presented their own thin external keyboard developed under the supervision of Artem Rodichkin from the company RosGeoProyekt. The new device is thinner and significantly more affordable than its analogs.

The keyboard connects to the main device, a smartphone or tablet, via a USB Type-C interface and is assembled from accessible materials (the prototype’s total production costs are less than 1,000 rubles). Only 16.5 cm by 7.5 cm in size, the keyboard can fit into the palm of a hand. This is partly because the new device doesn’t have a body: the keys are planted directly on a printed circuit board with no keycaps. Thanks to these engineering decisions, the device is only 3 mm thick.

Those are not all the changes to the more conventional external keyboard: the new device’s compactness is ensured by changes in the traditional key layout. There are only 55 keys, organized in such a way as to bring the most commonly-used ones to the top and hide the rarest letters (for the Russian layout) under a special function button.

Ivan Osetrov and Elizaveta Lokun. Photo by Dmitry Grigoryev / ITMO.NEWS

Another novelty in the students’ keyboard is the principle behind its support for superfast typing. In existing analogs, a keyboard matrix circuit is used to read the keys that are being pressed. It looks like a network of vertical and horizontal wires that cross under each key, while diodes are used to prevent false activation. Thus, whenever a user presses a key, the wires under it touch and close the circuit, sending current along the keyboard. In its turn, the operating system reads this data, producing a symbol on the screen.

“We’ve come up with a more efficient method. In our keyboard, we send the current down horizontal lines one by one and monitor the current on the vertical ones. If a key is pressed, the current goes down pins (small outputs of the controller circuit) connected to the vertical lines. So, in this case a user’s finger acts like a resistor: it touches a key, closes the circuit, and a symbol appears on the screen. There’s no need to use diodes in this design,” explains Elizaveta Lokun.

Apart from a physical prototype, the students released a software version of the keyboard that can convert a smartphone into a laptop keyboard. The developers intend for the software version to be used as a trial run to help interested users see if they are comfortable with the 55-key layout.

Within the next month, the team is planning to add several more components to the prototype, including keyboard backlight diodes for typing in the dark and a more compatible controller chip, RP2040. As for the software version, the team is planning to improve its key layout. After that, the students are hoping to order the production of the first batch of devices (about 30 items), as well as commercialize their solution.