From edible packaging to spherical robots

The exhibition of projects by young scientists takes place at ITMO on an annual basis; this year, however, was the first time that it was held as its own event. In addition to the young scientists themselves, it also involved potential sponsors, school students, and university students from different regions of Russia.

“Many came from other cities, as they plan to apply to ITMO. Here, they got an opportunity to meet members of the university’s scientific community, establish connections, and join projects. Besides, we’ve wanted to attract new applicants to the university’s Master’s and PhD programs. There were commercial partners here, too, including representatives of Gazprom,” notes Ekaterina Burakova, one of the exhibition’s organizers.

All of the projects on display went through several stages of selection. In the first stage, heads of ITMO’s laboratories, centers, and schools would recommend the most polished projects. Following a review by the university’s scientific and technological board, 38 projects passed into the final stage.

The participants exhibited projects in more than a dozen subject areas: from infochemistry and chemical engineering to food technologies, robotics, and artificial intelligence. Almost half of the projects tackled various environmental issues. That includes smart edible packaging (which also extends the product’s shelf life), biodegradable nano-fiber membranes for water and soil purification, and a reactor that produces hydrogen from water without contaminating the environment.

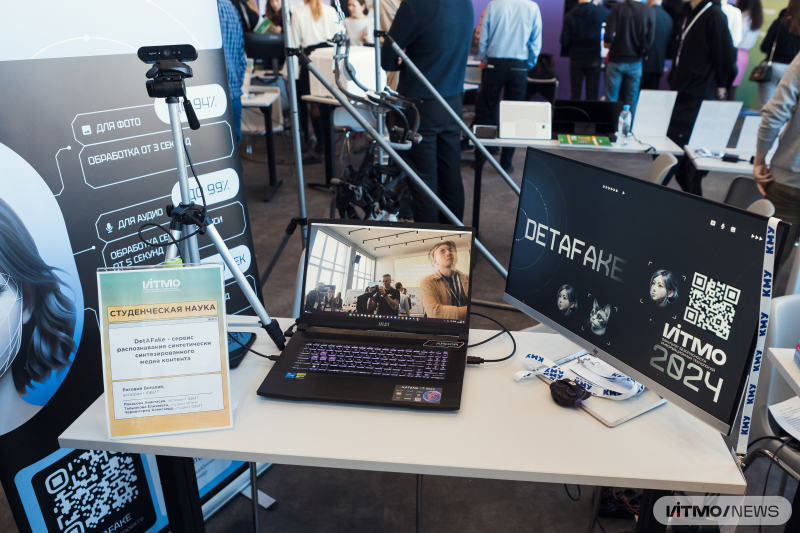

The young scientists dedicated their attention to other relevant issues, too. Notable projects included: a lower-limb exoskeleton for people with disabilities; test strips that can detect hydrogen peroxide, starch, and lactose in milk; an anti-fraud deepfake detection service; and software that assesses the quality of petrol in real time.

Small e-cycle with big ambitions

Among the visitors, a compact e-cycle prototype proved to be one of the most popular. At first glance, it may resemble a children’s bicycle, but the miniature vehicle may just become an alternative to weighty e-scooters.

The e-cycle weighs 12 kilograms, can cover 50 kilometers on a single charge, and reaches speeds of up to 70 kmph. It works on eight built-in batteries that can be fully charged in two hours.

“A smartphone mounted on the e-cycle uses Bluetooth to transmit data from the engine: the speed, battery charge, engine RPM. You can even set the maximum engine temperature, speed, and other basic parameters,” says Ivan Osetrov, a student at ITMO’s Research and Educational Center for Photonics and Optoinformatics.

The vehicle was made lighter with the help of PETG, a special plastic used as the main material of the e-cycle’s main body. Most parts were made not by hand, but 3D-printed. In addition, the creators got rid of some non-essential parts during assembly.

“Originally, the rear light came with turn indicators, but we decided to remove them since they aren’t always seen on the road, they’re hard to reach, and all the extra electronics can be a nuisance,” explains the engineer.

The e-cycle prototype at the exhibition. Photo: Dmitry Grigoryev / ITMO.NEWS

The e-cycle is said to cost around 100,000 rubles. According to the creators, if demand is high enough, larger models may be offered: not just size S, but M and L, too.

Now, the project team plans to use the e-cycle as a basis for a personal electric car for delivery workers. Here, too, the size will be an advantage: the proposed vehicle would only weigh around 25 kilograms. The e-car will be able to reach 90 kmph and cover 100 kilometers on a single charge. The approximate cost would be close to 300,000 rubles.

A new modular charging device for electric transport was also showcased at the exhibition. The device is easily adaptable and can be scaled to different formats: a charging system or a battery suite. The control system simply activates the necessary number of charger blocks and begins the charging process. According to the creators – Mark Novikov, a Master’s student at the Faculty of Control Systems and Robotics, and Mikhail Gostev, an ITMO graduate – the device can even charge phones and laptops, as long as the right adapter is available.

Better living through… carbon dioxide?

Is it possible to make money from air? And polluted, harmful air, at that? Yes, say the creators of a reactor that converts carbon dioxide into high-added-value products like ethylene, methane, and others. The system uses electrocatalysis: with the help of copper catalysts, molecules of carbon dioxide are transformed into various chemical compounds.

“During these reactions, depending on the size and shape of the catalyst, we can get ethylene, methane, or other substances. But our device is tailored the most towards ethylene, which can then be synthesized further or polymerized. Ethylene is a relatively expensive product: one ton of this gas can cost up to $1,000,” explains Danil Nikitenko, a Master’s student at ITMO’s ChemBio Cluster.

At the moment, the project is in the pilot stage. But within just six months, it has grown from a 50-millimeter laboratory setup into a full-fledged system that can perform tests in close to real-life conditions – and has garnered the interest of industrial businesses. The creators’ main goal is to scale up their reactor for industrial use. In addition, they plan to adapt the technology to function off alternative energy sources, making it even more environmentally friendly.

A safe alternative to quartz lamps

Another way to purify air from organic compounds – though this time in enclosed spaces – has been proposed by the creators of a photocatalytic filter. Its working principle is the same as in germicidal quartz lamps. However, the difference is that this new system is less harmful to humans and the environment, say the developers. It is also several times more effective and longer-lasting. The device itself is based on UV diodes and a film photocatalyst.

“Ultraviolet radiation can destroy organic compounds on its own, but if we add a catalyst, the process can be accelerated further. We replace the familiar ultraviolet mercury lamps with soft blue UV diodes, which are harmless to humans and don’t produce ozone. Thus, the device can be used in enclosed spaces and left to run permanently,” says Andrey Shelemanov, a PhD student at the Research Center for Optical Material Engineering.

Andrey Shelemanov. Photo: Dmitry Grigoryev / ITMO.NEWS

Another advantage of the technology is that its output can be increased without significant changes in size.

“If you want to expand the filter, all it takes is to add more diodes, more plates, more diodes, more plates, and so on. The denser it is, the more effective.”

The creators, who are implementing their project as part of the ITMO.Collab initiative, are already conducting tests outside the lab, using the facilities of a potential customer.

“We’re currently testing it at Microbox. The company makes products used in growing sprouts for agricultural use. One of the problems they have is that when seeds are sprouted indoors, the environment is humid and attracts bacteria and fungi, causing some of the sprouts to die. If we can reduce the percentage, we’ll increase the final harvest,” says Andrey Shelemanov.

Photocatalytic air purification system. Photo: Dmitry Grigoryev / ITMO.NEWS