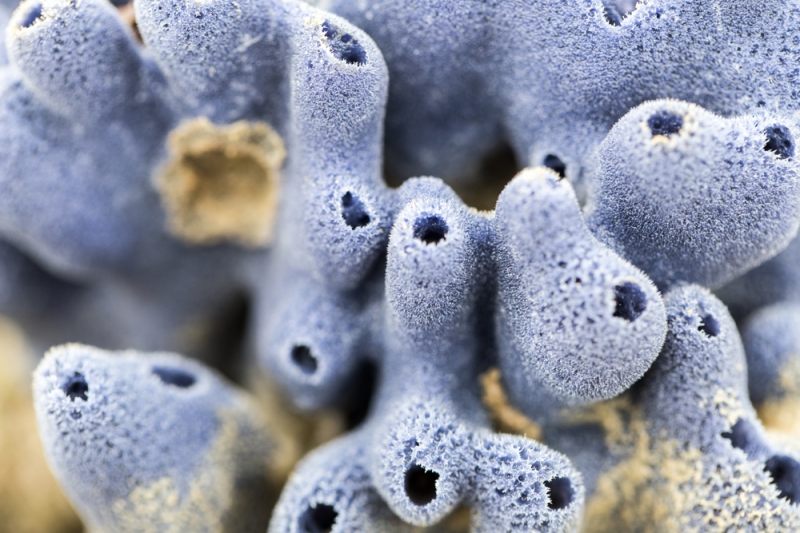

Sea sponges (Latin name Porifera) are some of the most ancient multicellular organisms. They have resided on Earth for over 500 million years, having survived numerous global extinction events. Their survivability is largely owed to their strong porous skeleton that consists of spongin, a type of collagen protein.

Since ancient times, humans have used sea sponges in everyday life and to prepare concoctions, or even to produce works of art. With the emergence of numerous synthetic materials, the demand for natural sponges fell. Recently, however, they’ve become the subject of a major international research project that involves scientists from Germany, Russia, the USA, Poland, and France and is headed by Hermann Ehrlich, founder of the field of extreme biomimetics and a professor at the Freiberg University of Mining and Technology (Germany).

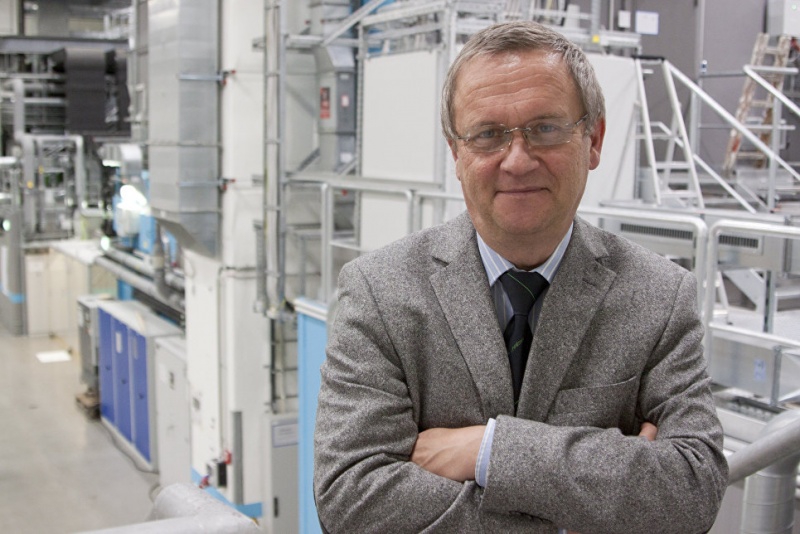

“We’ve spent a long time studying the various possibilities for producing materials based on hybrid structures,” explains Professor Sergey Molodtsov, head of ITMO University’s Transnational Scientific and Education Unifel Center for Advanced Methods of Materials Research. “These hybrid structures are comprised of a biological framework combined with non-organic materials such as metals and semiconductors. At some point, we asked ourselves – why not sponges? It’s a porous material that we can use for the same purpose.”

Sponge to graphite

In the course of their experiments, the researchers have studied sea sponge skeletons using various types of microscopes, conducted photoelectron spectroscopy, and analyzed their molecular and electronic structure.

“To provide a full account of any system, be it natural or synthetic, you need to know everything down to the location of atoms and the movement of electrons. We ended up using a large number of experimental methods that allowed us to provide a full rundown of the system,” explains professor Molodtsov.

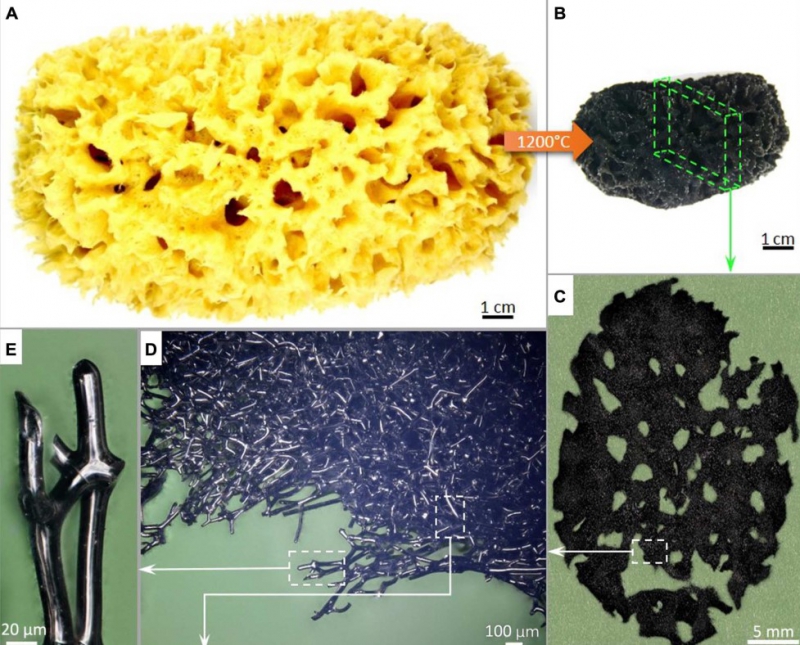

Then, the researchers studied how the material that makes up a sea sponge skeleton would behave in extreme conditions. It turns out that spongin, unlike other collagen proteins that make up the bones and ligaments of living creatures, does not turn to dust under high temperatures and retains its porous structure. When heated to 1,200 degrees Celsius in a smelting furnace, the skeleton lost up to 70% of its volume, but retained its micro- and nanostructure. The resulting porous graphite structure was firm enough that the researchers were able to saw through it without having it fall apart.

The secret to the heat-treated spongin-turned-graphite’s resilience is that the material retains the structural motif (the sequence of nucleotides or aminoacids) of its collagen structure. That means that the basic three-dimensional sponge structure remains unchanged even under such high temperatures. This is the first time that this phenomenon has been described.

Practical applications

This unique feature may have long-term benefits for the scientists involved in the production of new materials, especially those dealing with catalysts. As the authors of this study have shown, the resulting graphite tube can be metallized using copper oxide, producing an effective catalyst for the removal of nitrophenols from fresh- and saltwater. The addition of other metals can result in the creation of other catalysts.

“We could create a material that would work as a catalyst in car engines, dissolving harmful emissions before they pass into the exhaust system,” continues Sergey Molodtsov. “Another possible application is in the production of oxygen. There’s a lot of talk right now about the switch to hydrogen fuel, which produces exclusively water steam when burned. But to produce hydrogen, we need to perform a catalytic reaction. We need a catalyst that would split water into molecules of oxygen and hydrogen, and metallized sponges can do just that.”

A sponge’s biggest advantage is its high porosity, which means more area in which a reaction may take place. The accessibility of sponges is also a factor, as they can be grown using aquaculture techniques. Finally, unlike synthetic materials, sponges are natural products and are much more environmentally-friendly.

Prospects for other materials

In the future, the researchers plan to continue studying the possibilities of hybrid materials based on the tissue of marine multicell organisms. According to Prof. Molodtsov, the existing results can already have various applications.

“This field of research will continue to develop. Humans have exhausted their ability to produce complex synthetic materials easily, at low cost, and in a way that doesn’t harm the environment,” he says. “We have already produced some fascinating results with sea mushrooms, which grow 3 to 4 kilometers below the surface. These mushrooms’ stalks are incredibly flexible yet tearproof. At one point, NASA had the notion of launching satellites using the Earth’s centrifugal force. They would have grabbed a very long rope and spun it around the globe – a material similar in properties to those mushrooms would be able to accomplish that. We’ve already found out that these stalks are composed of silicon oxide, which makes them so durable. The stalk itself is porous, and the pores are filled with proteins that make the entire structure flexible.”

Reference: Iaroslav Petrenko, Adam P. Summers, Paul Simon, Sonia Żółtowska-Aksamitowska, Mykhailo Motylenko, Christian Schimpf, David Rafaja, Friedrich Roth, Kurt Kummer, Erica Brendler, Oleg S. Pokrovsky, Roberta Galli, Marcin Wysokowski, Heike Meissner, Elke Niederschlag, Yvonne Joseph, Serguei Molodtsov, Alexander Ereskovsky, Viktor Sivkov, Sergey Nekipelov, Olga Petrova, Olena Volkova, Martin Bertau, Michael Kraft, Andrei Rogalev, Martin Kopani, Teofil Jesioniowski and Hermann Ehrlich. Extreme biomimetics: Preservation of molecular detail in centimeter-scale samples of biological meshes laid down by sponges, Science Advances. 2019, 10.1126/sciadv.aax2805