Diagnosis a breath away

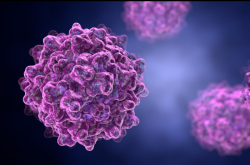

Helicobacter pylori infects the human stomach and the first part of the small intestine, where it settles in the mucus membrane, producing the urease enzyme. This increases acidity (pH), as well as the concentrations of ammonia and carbon dioxide, which leads to inflammation. Helicobacter pylori is responsible for chronic gastritis and peptic and gastric ulcers. Moreover, it can cause stomach cancer.

There are several ways to detect the bacteria: checking the blood for its antibodies; running bacteriological or microscopic testing; or conducting a rapid urease test during gastroscopy.

All of these tests either involve unpleasant procedures or require biological samples. However, there are also less invasive methods of diagnostics, such as urea breath testing. It compares the concentration of 12C and 13C carbohydrates in the carbon dioxide exhaled by the patient. The full procedure goes as follows: first, the patient exhales the baseline sample into a tube; then, they ingest a solution enriched with 13C which interacts with the bacteria, producing more CO2 and ammonia; after that, the patient exhales the second, diagnostic, sample. Then, the 12C to 13C ratio is analyzed in both samples. If the diagnostic sample contains more 13C, it is a sign of Helicobacter pylori infection.

Importantly, other factors, such as the patient’s age, sex, and eating habits, can have an effect on the 12C to 13C ratio. Moreover, the samples are usually analyzed with a non-dispersive infrared spectrometer, which is not always accurate – so that sometimes patients have to do several breath tests. At the same time, more accurate diagnostic systems, such as those based on mass spectrometry, require more complex and expensive equipment.

Photo by Dmitry Grigoryev / ITMO.NEWS

The novel device

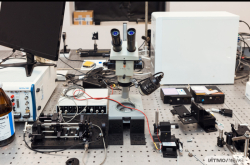

Researchers at ITMO’s Research Laboratory for Spectroscopy of Biological Objects developed a diagnostic system for urease breath testing that relies on Raman spectroscopy. According to the developers, this method is easier to use and can produce accurate results. Moreover, a significant share of the new device’s parts originates from Russia or the CIS nations, making it less dependent on the international market.

“This project was based on the Raman gas sensor we’d developed for the company Monitoring. The sensor detected 12C and 13C concentrations in CO2 and methane, which is important in production of gas mixtures. Having completed the project, we started thinking about its other potential applications and decided to focus on urease breath tests, a method commonly used in medicine. We succeeded in producing a simple and user-friendly diagnostic system based on Russian-produced components,” says Evgeny Popov, the device’s developer and the head of the Research Laboratory for Spectroscopy of Biological Objects.

Evgeny Popov. Photo by Dmitry Grigoryev / ITMO.NEWS

In order to adapt the Raman gas sensor for medical use, the researchers equipped it with a diagnostic system: a sample holder containing the gas mixture and a gas system that connects to test samples.

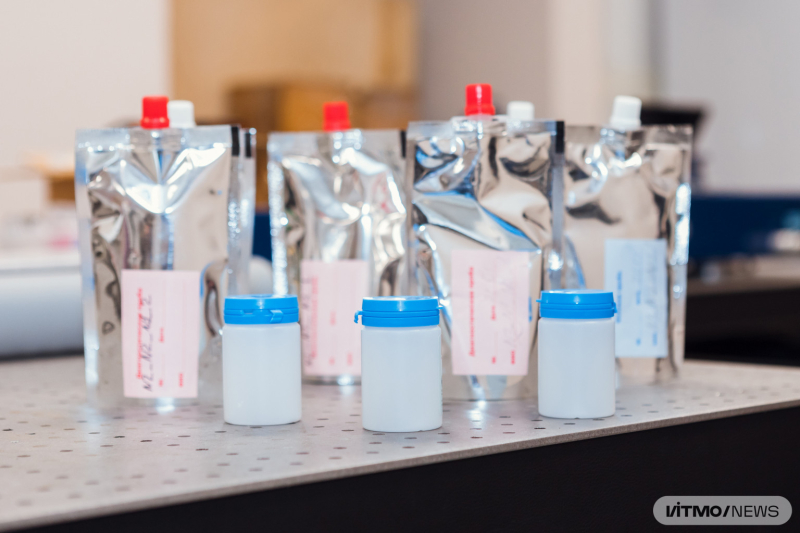

The new system was developed in collaboration with scientists from the D. I. Mendeleev Institute for Metrology, who prepared the reference gas mixtures – those where the volume ratios of all components are known. Such samples can be used to test and calibrate the system: if the ratios identified by the device are the same as those in the reference mixture, then the system is accurate.

Having complemented the device with the software used to manage the system and analyze samples, the researchers studied the effect of different parameters (power of laser radiation, temperature, pressure) on the concentration of 12C and 13C in the gas mixture. As a result, they were able to build a linear function that describes the dependency of 12C and 13C volume ratios on testing conditions. Thanks to this, the scientists can now choose the necessary parameters for testing and predict its results.

See also:

Medical Solutions, Exoskeletons, and New Foods: Latest Projects by ITMO Students

Before the start of testing, urease test samples (typically contained within sealed tubes) are connected to the box-like gas sensor. Once the gas mixture is within the machine, it goes to a closed container with small holes in its walls, which serves to prevent the mixture from spreading everywhere inside the device. Then, thanks to the device’s optical system, laser radiation is focused within the container.

The interface of the software developed to manage the new device. Photo by Dmitry Grigoryev / ITMO.NEWS

Once laser radiation hits gas molecules within the container, it sends photons through its holes, which are then picked up by the second optical system within the device and sent to the receiver.

Last comes the analysis. A monochromator and a camera detect all changes in the wavelength. This data is then used by the software to analyze the changing ratios of 12C and 13C. Finally, based on test results and other patient information, clinicians can determine the diagnosis and recommend treatment.

A special cleaning system prepares the gas sensor for the next testing by removing any residue of the already analyzed gas mixtures. This also contributes to the device’s accuracy.

Photo by Dmitry Grigoryev / ITMO.NEWS

More than Helicobacter pylori

Currently, the system’s developers are looking for partners among medical laboratories to run preclinical and clinical trials. If those succeed, the team will proceed to look for industrial partners who will help produce the device. According to Evgeny Popov, the diagnostic system can be of interest in the industry because it can be used in place of its foreign-made analogs.

“What’s the whole process like? Two samples obtained during a patient’s urease breath test are taken to a medical lab to be analyzed with our device. There, the operator connects the tubes to the sensor and conducts the necessary calculations using our user-friendly software. By following its cues, specialists will be able to follow the procedure exactly as we intended, which is crucial for the result. Once the test is complete, the operator will get a printout of the changes in 12C and 13C volume ratios. This document can be sent to a clinic or the patient, as well as used to make a clinical protocol for the lab,” explains Vladimir Vitkin, the head of the Laboratory for Optoelectronic Support of Cyberphysical Systems.

In the future, the system can be adapted for diagnostics of other diseases, such as diabetes, asthma, lung cancer, and tuberculosis, all of which affect the contents of a patient’s breath and are characterized by specific biomarkers (carbohydrates, aldehydes, alcohols, ketones, and others).