Invisible danger

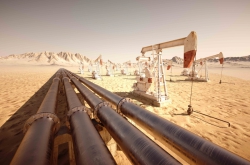

Refined products are omnipresent in both manufacturing and our everyday life. Fuel oil is used to power ships and heat homes. Gasoline serves not only as an automobile fuel but also as a paint solvent. And bitumen is known for its waterproofing properties and is common in the construction industry, notably for roadwork.

Though widely-common, these materials can be harmful for people. The burning of petroleum products releases carbon dioxide and methane emissions, which infect the human bloodstream, resulting in oxygen deprivation, neurological problems, shortness of breath, and suffocation (in case of methane exposure).

Catching the intangible

The question is: “How can we detect hazardous gasses if they have neither odor nor color?” The most common means for this in the workplace, be it oil, gas, or mining production, is gas detectors located around the venue perimeter.

These devices can automatically detect gas leaks using a detector made of various metals, including lead selenide-based chalcogenide films, which are up to 1 micrometer thick and sensitive to infrared radiation.

The technology detects a gas leak in several tens of microseconds and can provide greater accuracy when heat-treated. The technique, however, is not perfect. The films need to be annealed in open furnaces, which makes it a complex process that requires human involvement, albeit cannot guarantee that no defects will occur in production.

Read also:

Cheap and Simple Method of Detection of Harmful Gases Suggested by ITMO Researchers

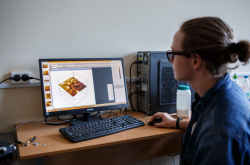

A 3D model of the detection system developed by Anastasiia Olkhova. The detector consists of an infrared radiation source, a cuvette filled with gas, a detector (a chalcogenide film), an analog-to-digital converter, a programmable controller, and a system of thermal sensors. Model provided by Anastasiia Olkhova.

What ITMO researchers suggest

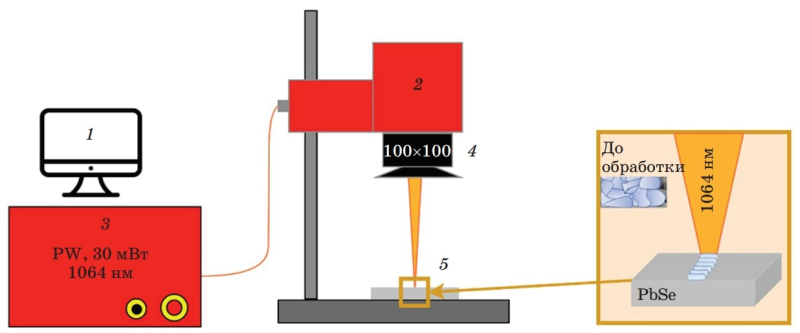

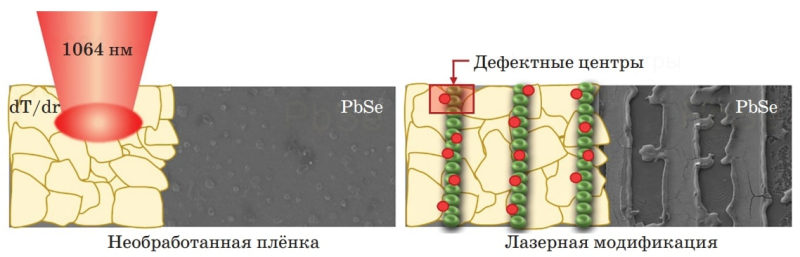

Researchers from ITMO’s Institute of Laser Technologies came up with an alternative to thermal heat treatment in an oven – and that is laser modification. As part of their research, the scientists applied lasers with 405 and 1,064 nm wavelengths, managing to improve the optical and electrical properties of the chalcogenide films.

“We modified chalcogenide films and placed them in a specially-developed prototype of an optical gas detector. After the treatment, the film reflection dropped to 10% in the visible wavelength range, affecting the near-infrared one, as well. As a result, the films grew more sensitive to infrared radiation, which had a direct impact on the accuracy of leak detection,” notes Anastasiia Olkhova, a senior researcher and a second-year PhD student at ITMO’s Institute of Laser Technologies.

Anastasiia Olkhova. Photo by Dmitry Grigoryev / ITMO.NEWS

The optical detector works as follows: when an infrared laser source illuminates the detector (the chalcogenide film), the latter records its electrical characteristics (resistance) in real time. If there is no gas flow, the characteristics remain unchanged. Otherwise, the gas begins to absorb infrared radiation from the source, which results in lower amounts of radiation in the detector – and hence a change in the registered characteristics. A signal about the accident is sent to the system, which, in turn, calls for emergency procedures.

Another advantage of the technology is that it is automated. It is enough to set the parameters of the laser once to produce the same films over and over again. Better still, the product does not require expensive equipment.

As noted by the developers, the method can be applied in oil and gas refineries, coal mines, and other industries and laboratories with the risk of gas leakage.

What’s next

The researchers plan to finalize their detector and technique. In particular, they are going to determine the minimum detectable gas concentration and make the method more stable to produce films of equally good quality. The creators hope that, in the future, the technology can be used to detect more types of gasses.

“The radiation source plays a key role in gas identification. So far, we focused exclusively on carbon dioxide and methane, however, hopefully, we will expand the method to hydrogen sulfides shortly. To do so, we need to leave the narrow-band light source behind and start to select radiation on the film itself. This will be a true breakthrough,” says Anastasiia Olkhova.

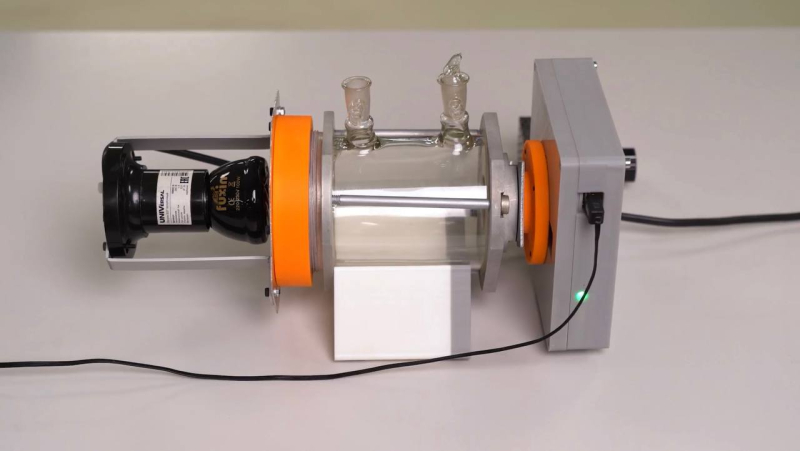

The prototype of the detection system. Photo courtesy of Anastasiia Olkhova

The study is supported by the Russian Science Foundation (grants No. 23-29-10081 and No. 19-79-10208).

With her technology, Anastasiia Olkhova became the winner of the Fifth Jubilee International Young Scientists Awards in the Field of Oil and Gas: A Glance Into the Future founded by Gazprom Neft to award young scientists for innovative developments in the oil and gas industry.

Reference: Anastasiia Olkhova, Alina Patrikeeva, Maria Dubkova, Natalia Kuzmenko, Nikolai Nikonorov, Maksim Sergeev. Comparison of CW NUV and Pulse NIR Laser Influence on PbSe Films Photosensitivity (Holographic Technologies: Theory and Practice, 2023).