Photon crystals are a promising material in rainbow holography. A simple example of this material is opal: this mineral consists of separate, ordered spheres that refract light. Thus, depending on the lighting angle, the stone’s color changes from red to blue. This effect can be used to create protective tags that can prevent counterfeiting; for instance, by creating images based on magnetic crystals that can only be identified with the help of a magnet.

The main challenge in this process would be to adapt the magnetic material to the image application method and create a 2D image out of it. Among the many methods probed for this was 3D printing, which is quite time- and labor-intensive.

Scientists from ITMO have come up with a simpler and quicker way to create ordered structures within 2D images made from magnetic crystals. In their method, they encapsulate the magnetic material inside a polymer matrix using ink jet printing. As a result, they can produce images that can change their color from red to blue depending on the distance from a magnet.

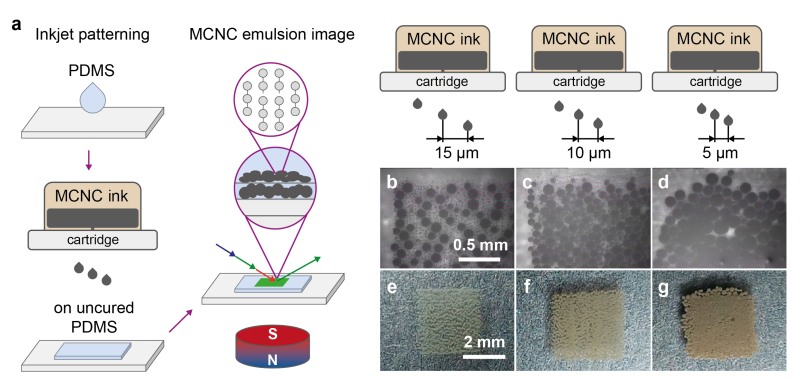

Left: schematic of the experiment. Right: results of printing with varied parameters. Images courtesy of the paper's authors

First, the researchers devised a method of synthesizing magnetite particles (a magnetic material that efficiently refracts light in the visible spectrum) and used solvothermal synthesis – a method in which nanoparticles are formed out of a solution of salts at high temperatures. Next, they coated the synthesized particles with polyacrylic acid, a stabilizing polymer that repels the particles from one another and improves their dispersibility, or the ability to distribute in a solution. Then, using a jet printer, the physicists “printed” ink made from magnetite into a polymer matrix, which hardens on the outside while allowing the ink inside to remain liquid and mobile.

“As a result, we acquired an ordered system: if a magnet is placed close to it, all the magnetic particles will assemble into a specific image, the color of which depends on the magnet’s proximity – it can be red, green, or blue. This technology can be used as an easily identifiable anti-counterfeiting tag. Using this method, we can quickly and precisely apply very small amounts of crystals onto a surface and use them to create tags that are cheaper and easier to produce than analogs. They can be used as authenticity tags for luxury or limited edition products, such as medications, jewelry, and musical instruments,” says the paper’s first author Artyom Smirnov, a first-year PhD student at ITMO’s ChemBio Cluster.

Next, the researchers are looking to find a more suitable image matrix. Currently, they are using dimethylpolysiloxane, a polymer permeable by vapor. This means that when the system is in use, the liquid will sooner or later evaporate from it, leaving magnetite particles unresponsive to a magnet. By solving this problem, the researchers will extend the tags’ service life, bringing them closer to real-life application.