A common way to protect metal products against counterfeit is by using special holographic stickers that usually have several degrees of protection – for instance, they include hidden images or are destructible. The latter is achieved by using several layers: if the uppermost one gets damaged when someone tries to take off the sticker, it destroys the entire trademark. However, this method is not 100% effective. For instance, by heating the sticker, malefactors can remove all of its layers without leaving any traces.

Moreover, holograms on such stickers aren’t unique – they are batch-produced using the same embossing matrix (creating a new one for each sticker would be expensive and time-consuming). Such stickers are made unique using topography, i.e., by adding special numbers or symbols to the image.

There are ways to print holograms directly on a surface, for example, with the interference method when two overlapping laser beams form micron and submicron structures. This method requires precision and exact calibration of the optical circuit, which consists of many optical elements – this means that special conditions have to be maintained for it to function properly.

However, there is a less demanding method that relies on self-organization of structures when materials are exposed to laser radiation. It was only recently that this technology was first used to create anti-fraud holograms with specific visual properties that could be recreated on a relatively big scale (1x1 cm). However, in such applications, the researchers didn’t account for the structures’ mutual effect on each other, which caused their instability and branching. Thus, it was impossible to create their protective properties.

Read also:

ITMO Researchers Find Way to Make Packaging Cheap, Easy to Apply

Mikhail Moskvin in the lab. Photo by Dmitry Grigoryev / ITMO.NEWS

A solution from ITMO

ITMO scientists have suggested a new way to control periodic structures using continuous dynamic changes of laser radiation’s polarization. With this method, the researchers can create structures with complex geometry and imbue them with visual protection properties.

As a result, the research team has come up with their own technology for printing 3D holographic trademarks on metal surfaces. The resulting structures are the same as those obtained with the interference method, but they require less equipment, thus making their production easier and more affordable.

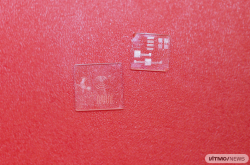

The technology works as follows: when surface electromagnetic waves are excited by focused laser radiation, they interfere with the laser beam. This results in desired structures forming inside the laser imprint. Photo by Dmitry Grigoryev / ITMO.NEWS

According to the developers, the new method will not require any additional optical elements, as in the two-beam system, which makes the production subject to fewer external factors.

With the new technology, the trademarks provide two levels of protection. First, the trademark’s visual effects – animation, movement of light, and 3D properties – make it possible to tell a fake from the original. Second, structurally, each trademark is unique and random, thus impossible to counterfeit.

Trademarks are designed using graphics software. Then, the designs are uploaded to a module that controls the polarization of laser radiation. Then, the laser etches the holographic trademarks on the steel surface of the product.

Compared to holographic stickers, the trademarks are nonerasable. They become an indelible part of the product and can only be polished off the surface, resulting in damage to the product.

Durable holographic anti-fraud trademarks. Photo by Dmitry Grigoryev / ITMO.NEWS

What’s next

The new trademarks can be used as anti-fraud protection on various metal products, such as watches or car parts. They are compatible with existing scanners.

“Currently, with our method it’s possible to make trademarks at the speed of 2.5 cm per minute, which is comparable with the efficiency of color laser marking or direct laser interference patterning. Next, we are planning to improve the module that controls polarization, thus improving the method’s performance. Then we will test the trademarks’ durability and adapt them to any metal surface, as well as make them multicolored. Additionally, we are planning to work on a technology that will create random trademarks with structures as unique as fingertips. Such trademarks can be used to create unique IDs for anti-fraud holograms,” shared Mikhail Moskvin, one of the creators of the new technology and a junior researcher at the Institute of Laser Technologies.

Mikhail Moskvin. Photo by Dmitry Grigoryev / ITMO.NEWS