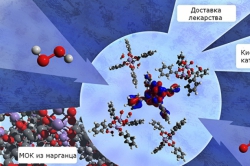

Framework materials are porous coordination polymers with regular crystalline structures. Due to slight variations in their composition, these materials are usually subdivided into different classes, with modular-structured metal-organic frameworks being one of the most scientifically peculiar. First discovered several decades ago, this class of framework materials has now taken the center stage in the contemporary chemistry research. With their large pores and regular crystalline structure, these polymers can be easily simulated in vitro, which is their main advantage. Moreover, because of the high adsorptive capacity, biocompatibility, and stability in biological media, metal-organic frameworks are extremely versatile, which makes them a go-to material in an array of different fields.

One popular use is the chemical reactions catalysis. Scientists draw on their high adsorptive properties when creating gas repositories and composition purification systems. What’s more, the crystalline and domain structure of these frameworks allows for using computer simulation when projecting structures with prerequisite properties, which has important implications for drug design.

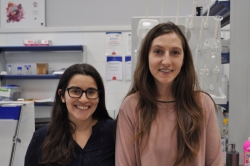

“Having a basic computer model of the framework enables us to simulate how the material properties change following a change in its composition or other conditions. This can be used for creating effective delivery systems of highly toxic drugs such as cancer treatments, which are notorious for their negative side-effects. By adsorbing the drugs to the pores of the framework structure, we can minimize the harm they cause,” explains SCAMT Laboratory researcher Anna Simagina.

The main advantage of the framework-based drug delivery systems is that they can make the delivery process much more controllable. Since framework materials dissolve very slowly, the drug is released in a much more graduate way. Moreover, the abundance of different carrier materials allows for choosing the safest and most stable structure for each individual case. Scientists have already successfully used a porous magnetite framework material to develop a highly effective thrombolytic enzyme delivery system. Its magnet-controlled framework particles are specially configured to a fast release of the drug substance, leading to a tangible reduction of the drug dosage and experienced side effects, and an increase in overall treatment efficiency.

“It would have been impossible to make such a breakthrough within the realm of just one scientific field. We are actively collaborating with specialists from other fields such as biology, chemistry, physics, and medicine to advance the use of rational design in modern chemistry and pharmacology,” comments Evgeny Pidko, professor at Delft University of Technology and head of the theoretical chemistry research group at SCAMT Laboratory.

The scientists note that by providing tools for simulating the behavior of drugs adsorbed in framework structures, theoretical chemistry can make a significant contribution to interdisciplinary scientific research in this field. The drug is released during the destruction of the framework, and this can be easily and accurately simulated. Theoretical chemistry scientists can forecast exactly how a framework will dissolve when affected by changes in different external factors such as acidity, temperature, or substance concentration. This is the focal question of a paper that has recently been published by SCAMT researchers.

“We’ve established which molecular processes will occur when framework structural units is exposed to oxygen or hydrogen peroxide. Later we plan to expand our research remit to simulating the whole framework material at the nanoscale. In terms of theoretical chemistry research, it’s a very ambitious goal. But we believe that our findings will help to create a new generation of highly effective and safe drugs,” says SCAMT Laboratory researcher Mikhail Polynski.

Reference: Towards rational design of metal-organic framework-based drug delivery systems. A. A. Simagina, M. V. Polynski, A. V. Vinogradov, E. A. Pidko. Russian Chemical Reviews, 29 July 2018.