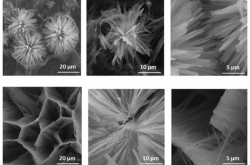

Spider silk is well-known for its mechanical properties: for one, it possesses great strength and comparable elasticity, which make silk-based fibers several times tougher than kevlar used in body armor. For that reason, spider silk is an excellent option for materials that need to withstand heavy loads.

What’s more, this material is not only naturally durable and flexible, it is also biodegradable and biocompatible. Due to that, spider silk is regarded as a promising material for medical applications, namely implantology and tissue regeneration. Some researchers have already demonstrated that spider silk can be used to produce artificial muscles, while others learned to make medications for targeted delivery using silk with alloy nanoparticles.

Here is how it works: specialists add liposomes – microscopic spheres, with shells made of the same molecules as cell membranes – into a biological sample. Their similarity enables the liposomes to freely penetrate biological cells. Medications are placed inside the liposomes and coated with a layer of nanoparticles on top. The particles are sensitive to external influences, be they laser-induced or electromagnetic in the case of magnetic particles, which cause them to heat up and destroy the protective shell of liposomes, leading to targeted drug release.

The solution from ITMO

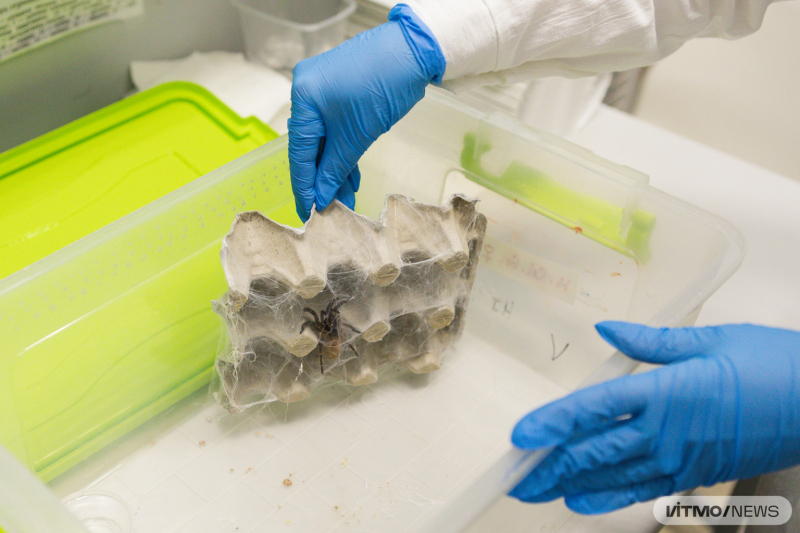

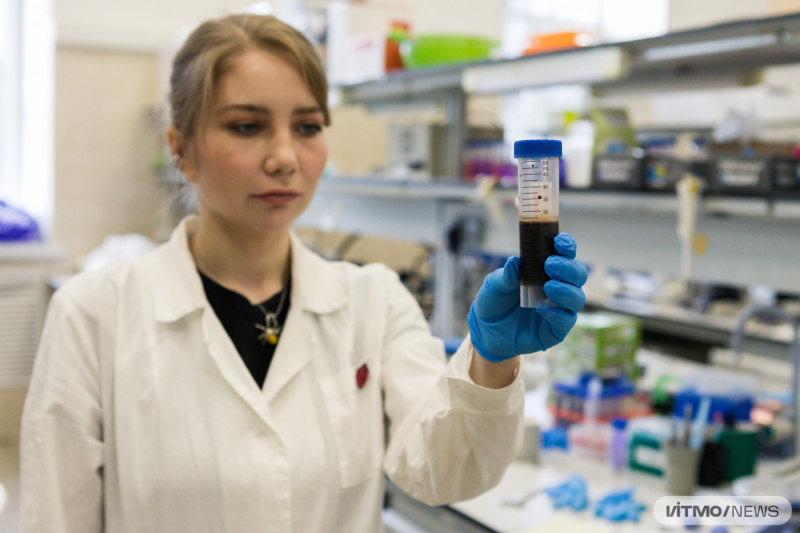

Researchers from ITMO’s ChemBio Cluster under the supervision of PhD student Anastasia Kryuchkova developed a new material composed of the Linothele fallax spider silk and a coating of magnetic nanoparticles to potentially be applied in targeted drug delivery, as well as cartilage and joint tissue regeneration.

Tissue degradation, caused either by an injury or due to wear and tear, is a common medical condition that calls for implants or microfracture. Microfracture is a surgical technique that works by creating several fractures in the bone to fill the injury site with bone marrow stem cells as a source of osteoblasts, which then differentiate directly into bone tissue cells (osteocytes).

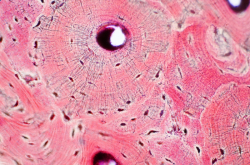

To ensure the osteocyte-rich blood stays in the regeneration area, the fractures are covered with a special membrane – or a scaffold (a structure providing support for subsequent tissue development). The researchers realized that spider silk is the perfect candidate for a scaffold due to its exceptional mechanical and physical properties. Its biocompatibility minimizes the risk of rejection and biodegradability ensures that the material decomposes naturally once it does its job.

A Linothele fallax spider. Photo by Dmitry Grigoryev / ITMO.NEWS

How the material works

The particles heat up when exposed to an external magnetic field yet because of the unique makeup of the particles, the heating temperature can be precisely regulated. Controlled heating destroys liposomes and causes medication release at the injury site, providing targeted effects. At the same time, the silk threads themselves facilitate directional growth and serve as a support system for cells.

The specialists employed fibroblasts as tissue regeneration model cells to test the biocompatibility of the produced material. Commonly known for synthesizing collagen, elastin, hyaluronic acid, and other key components, fibroblasts play a crucial role in tissue remodeling. They can be reprogrammed into chondrocytes – the cells that make up cartilage tissue – through certain tissue growth factors and bone proteins.

The in vitro experiments showed that spider silk fibers coated with magnetic nanoparticles promote the synthesis of cartilage tissue from fibroblasts, and controlled temperature allows for targeted drug delivery when exposed to an alternating magnetic field.

What’s next

The research team and medical organizations are actively negotiating potential collaborations. In particular, the scientists are planning to create silk-based implants for meniscus regeneration jointly with the team of the Department of Traumatology, Orthopedics and Disaster Surgery at Sechenov University.

At the same time, they also consider replacing spider silk with silkworm fibroin, which is more affordable and scalable, and employing 3D bioprinting when producing the scaffolds in the future:

“The SCAMT Institute is actively pursuing bioprinting. If earlier we produced scaffolds manually, now we plan to use bioprinting instead. Moreover, we will mix silk with other components to obtain hydrogels that can be used for various tissue regeneration technologies,” concludes Anastasia Kryuchkova, the first author of the paper and an engineer at ITMO’s ChemBio Cluster.

Anastasia Kryuchkova. Photo by Dmitry Grigoryev / ITMO.NEWS

Reference: Anastasia Kryuchkova, Artemii Savin, Aleksandra Kiseleva, Marina Dukhinova, Elena Krivoshapkina, Pavel Krivoshapkin, Magnetothermal spider silk-based scaffolds for cartilage regeneration. International Journal of Biological Macromolecules, 2023.