Why it’s hard to combine movement and energy efficiency in robots

Industrial robots need to move with high speed and precision. These are achieved with powerful electric drives that are very demanding in terms of the energy they consume. This means that such robots often need to be connected to a power outlet, making them stationary.

Mobile robots are a whole other matter, however. They have to be designed in a way that allows them to perform all their tasks with just the energy they can get from a battery. And it can’t be the case of just increasing the battery’s capacity either – here, “more powerful” also means “heavier.” If a robot wastes half the energy gained from a heavier battery just to carry this battery around, it’s not a very efficient robot. That’s why researchers engineer robotic systems in a way that will make use of the mechanism’s inherent dynamics, thus requiring less energy.

Overcoming the challenge

In robotics, such mechanisms are designed with morphology in mind. This means that most of the dynamics needed for the robot’s movements are provided by its body (the spread of its weight, its elasticity, or mechanical links). The control systems for such robots don’t need to program their every move, instead focusing on supporting its existing dynamics.

When designing such robots, engineers must follow a formalized process that takes into account not only control algorithms, but also the design of the robot’s mechanics. According to Ivan Borisov, an engineer at ITMO’s Research Center “Strong AI in Industry,” for a long time robotics specialists concentrated on developing new algorithms while still using the same hardware and principles as in industrial robots.

However, the success of Cassie the robot has shown that in order to achieve high speed, robustness, and capacity to navigate unstructured environments, robots need to be designed differently. First and foremost, they need to be adaptive and energy efficient.

The method from ITMO

ITMO scientists used the principles of morphological design to suggest their own method of designing mechanisms for manipulator, locomotion, and wearable robots. The method is based on a three-step algorithm.

First step: creating an open kinetic chain. Here, the algorithm determines which parts should make up the mechanism and the trajectories they need to follow in order to produce the desired movements.

Second step: closing the chain of parts that make up the mechanism (the kinetic chain is closed when each link in the chain has over two connections). Here, the algorithm determines which links in the chain need to be connected to the core mechanism so that a drive can be transported to a different joint. At this point, the program may also decide to remove or add certain connections in order to lower inertia. This helps preserve energy and speed up the robot.

Third step: placing electric drives with maximal efficiency. At this stage, physical and virtual elastic elements are also integrated into the mechanism. With these, the robot can adapt to the environment, cushion itself against rough and uneven surfaces, and conserve energy.

By targeting performance and maximum functionality at every step, this approach produces more efficient devices.

Ivan Borisov. Photo by Dmitry Grigoryev / ITMO.NEWS

“Using our method, we can develop any leverage mechanism, such as a leg mechanism for a walking robot, a finger mechanism for a grasping device, or parts of an exoskeleton. What’s even more, we can make robots that are able to function in unstructured or unknown environments. For instance, a walking robot that will be able to map out their surroundings even in bad lighting or an anthropomorphic wrist that can grasp objects it can’t see,” explains Ivan Borisov.

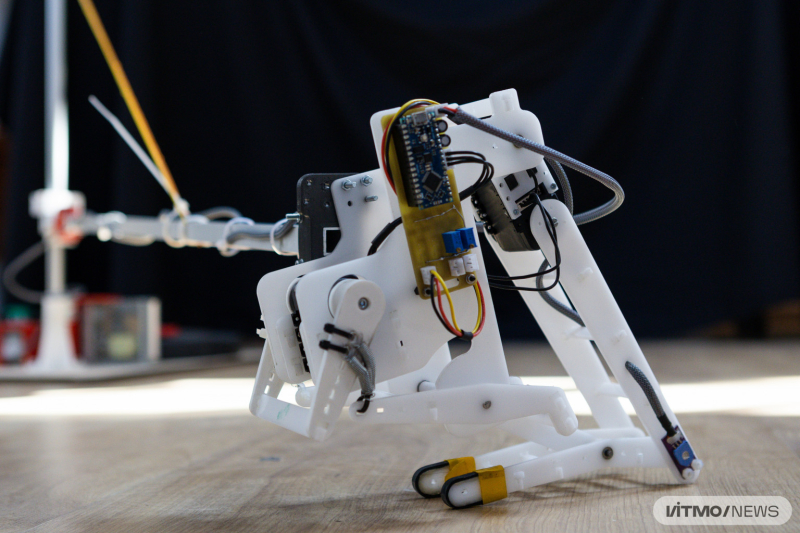

To demonstrate the algorithm’s capacity, the researchers developed a jumping robot that can move on uneven terrain. The robot moves thanks to self-sustained vibrations of its drive and springs; it can change the speed and direction of its movements. Thanks to the new method used in its design, the robot requires a drive four times less powerful than a similar robot designed with the classical approach.

According to Ivan Borisov, the method squeezes the most out of each part of the algorithm, maximizing the drives’ efficiency and using elastic parts to restore some of the used energy.

Flexible jumping robot. Video by Dmitry Grigoryev / ITMO.NEWS

What’s next

The new method will be presented at the prestigious IEEE International Conference on Robotics and Automation (SJR 1.92), where ITMO will be this year’s only Russian participant.

Additionally, the researchers are developing software that will use the algorithm to generate designs of walking robots and trajectories of their electric drives. It will also test the suggested solutions in a simulated environment.

A similar program for grasping devices has already been developed at ITMO. This one can design a robot based on the parameters of an object it needs to grasp. For instance, if you need a device for grasping apples, you need to simply indicate the fruit’s characteristics – then, the algorithm will generate the mechanism’s structure with optimal parameters.

According to the researchers, as the method involves randomization, it can produce several solutions for the same problem, allowing the human operating it to choose the best one.

Both algorithms are meant to assist designers in making mechatronic and robotic systems, including industrial, collaborative, or manipulator robots.