Experiments with cultures of cells or microorganisms are associated with a number of requirements: the lab needs to be sterile and a certain temperature has to be maintained inside, while all staff have to wear special uniforms. All of these conditions can be met in special culture chambers, which are stationary isolated laboratories. However, they are not really suitable for educational purposes because of their small capacity – only a few people can comfortably work inside.

A solution by ITMO scientists

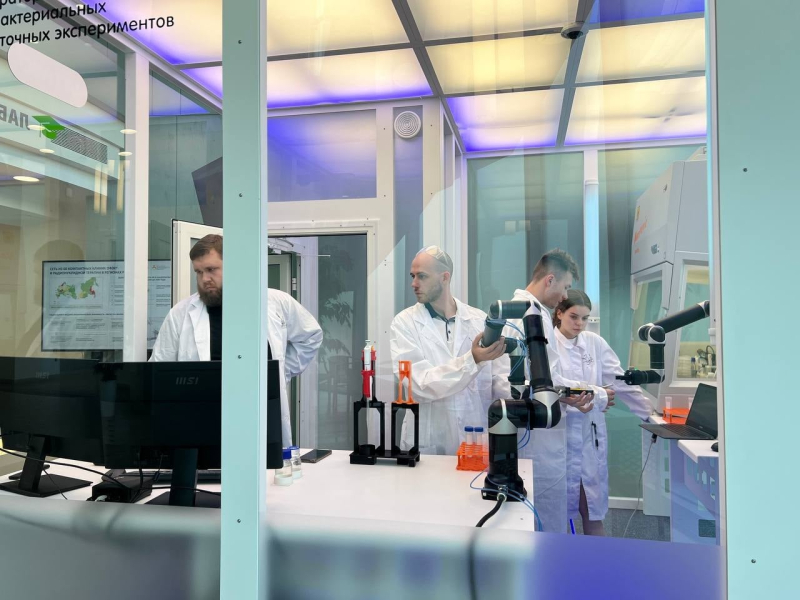

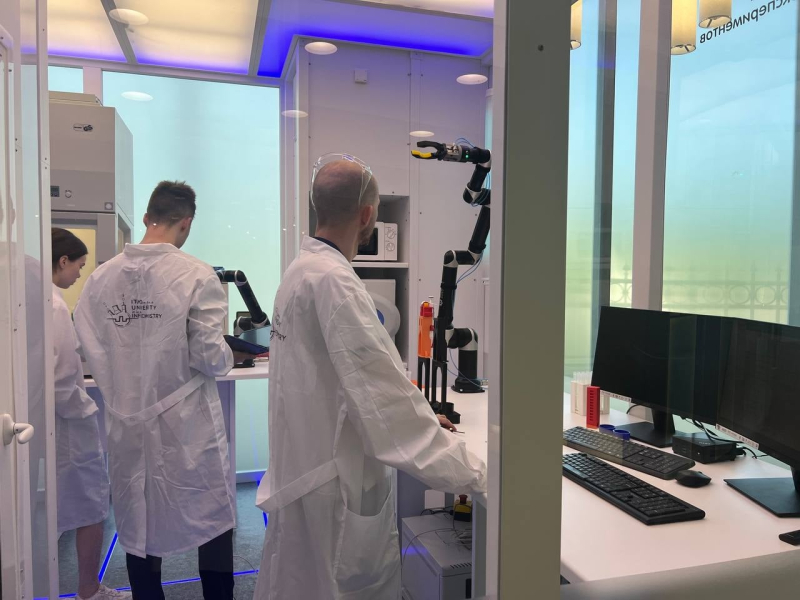

In collaboration with their partners, researchers from ITMO University have developed a mini laboratory for experiments with cells and bacteria that has recently been unveiled at the Almazov National Medical Research Centre. The transportable device is cube-like in shape, with each of its sides being 3 meters long. Inside is equipment for growing cell cultures: a laminar flow box that provides sterile conditions, a thermostat, a CO2 incubator, a microscope, a refrigerator, a water-bath, and a centrifuge. A robotic platform can also be integrated into the lab for analyzing materials with atomic-force microscopy. Additionally, the cube is equipped with high-efficiency filters for autonomous ventilation and additional sterilization. The new laboratory can serve several purposes:

Training. As the lab is autonomous, it can be assembled in any room, with no need to connect it to a ventilation system. Moreover, the lab’s walls are transparent, while pre-installed cameras record and broadcast the experiments conducted inside. This means that the cube can be used to demonstrate experimental procedures to school and university students.

Research. The lab is suitable for studies with eukaryotic (with nuclei) and bacterial (without nuclei) cells, which can be not only grown but also programmed using different approaches.

For such studies, scientists at ITMO grow various cell cultures on biopolymers and study their reactions and compatibility with different materials. Ultimately, such experiments will provide new solutions for regenerative medicine by optimizing cell reactions through managing the structures of materials. One particular upcoming study will look into the way cardiomyocytes (heart muscle cells) survive on different polymers. This experiment should prove helpful in understanding how cells can be caused to contract, paving the way for new heart implants.

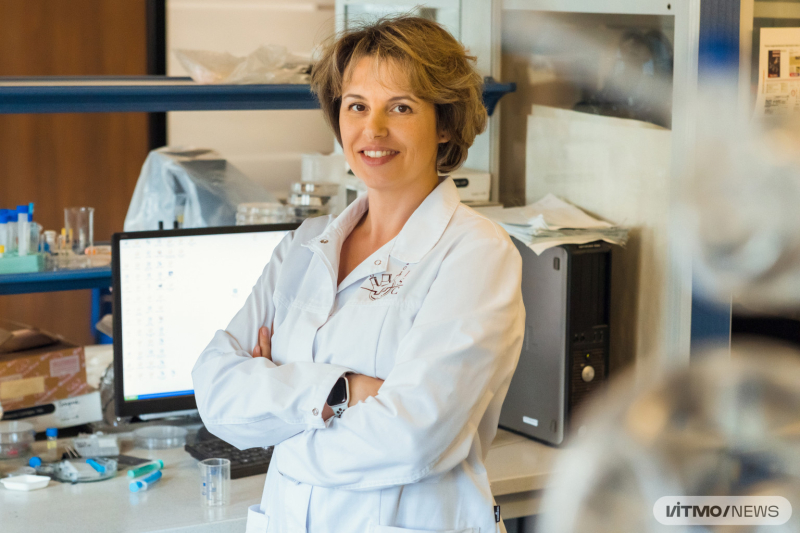

“At the lab, we engage in model tissue engineering – we grow human tissues and organs in a primary cell culture system. We cultivate cells on samples of biodegradable polymers with different micro- and nanostructures, and then we observe how cells react to these materials. Depending on the type of signals formed by materials, cells can stick to the surface of the materials, reproduce, grow into them, or die. Depending on cell reactions, we will develop the materials that would help us elicit the necessary cell behavior,” explained Ekaterina Shishatskaya, the head of the project and an ITMO Fellow.

Ekaterina Shishatskaya. Photo by Dmitry Grigroryev / ITMO.NEWS

Automated experiments. Additionally, the laboratory is equipped with a robotic manipulator that helps automate a part of the experiments. Currently, the device is capable of working with a human collaborator who has to deliver experimental solutions and supplies, as well as analyze experimental data using a microscope. The results of each study are uploaded into a database where they are analyzed by an AI algorithm that decides on the next series of experimental samples. In the future, the researchers are planning to make the entire process fully automated.

Snapshots of research in robotization of chemical technologies, developing labs-on-a-chip, and applications of smart materials for muscle contraction. Such studies will be conducted at the new laboratory. Video courtesy of ITMO’s Infochemistry Scientific Center

What’s next

In the near future, the scientists are planning to use the mini laboratory for studies involving organs-on-a-chip – miniature copies of tissues and organs. This way, by continuing the research on cardiomyocytes and biodegradable polymers described above, the scientists are hoping to develop a working artificial heart.

Among other future developments is the possibility to monitor the lab’s experiments remotely with a camera and a special microscope. Then, using machine learning, the researchers will form databases that can contribute to studies in the fields of regenerative medicine, cell biology, and materials science.

“One challenge for modern materials science is data collection and systematization. We are planning to solve it by involving citizen science – with our mini labs, school students will not only receive initial training in the field, but also collect data that we will be able to use in frontier research. For instance, it will help us predict the behavior of complex systems and materials for programming cell and bacterial cultures,” said Prof. Ekaterina Skorb, the head of ITMO’s Infochemistry Scientific Center.

Ekaterina Skorb. Photo by ITMO.NEWS

The project was created in collaboration with the Fund for Infrastructure and Educational Programs and the research and manufacturing association Prolab.