Contents

- The history of the institute

- Educational programs for all levels

- The institute’s research areas

- How to develop your own project

The history of the institute

The Institute of Laser Technologies takes root from the department of quantum electronics – the first one in the USSR – that was founded at ITMO (then-LITMO) in 1963 by Konstantin Krylov. Two years later, his student, now the research supervisor of the Institute of Laser Technologies, Vadim Veiko founded the university’s first laboratory of laser technologies, which expanded into a department of laser technologies in 1988. These departments existed separately until their merger in 2015.

Read also:

Holography, Space Science, and More: A Timeline of Science at ITMO

In response to the growing demand for specialists with competencies in a variety of fields and capable of interdisciplinary research, the university’s Faculty of Nanoelectronics transformed into the Institute of Laser Technologies. The Institute built upon the foundation laid by the two laboratories, including under its aegis the International Research Laboratory for Micro- and Nanotechnology Lasers, the Laboratory of Biomedical Laser Technologies, and the Laboratory of Industrial Laser Technologies.

“Currently, there is a demand for versatile specialists who can do anything: develop, fix, or improve lasers, invent new technologies or improve existing ones, and apply lasers for a variety of tasks – from slicing titanium to assembling nanostructures and metasurfaces. In our wide team, students don’t have to choose between laser methods and technologies, but can try their hand at everything at once. Moreover, in such an interdisciplinary environment, we can spot hot trends in science and technology, find applications for our ideas and bring them to the market and the industry,” explains Vadim Veiko.

Vadim Veiko. Credit: ITMO.NEWS

Educational programs for all levels

Bachelor’s program. Here, students can follow individual learning tracks that help them decide on their future specialization and focus on acquiring the skills they will need. There are four tracks within the Laser Technologies program:

- Researcher: understand the cutting-edge technologies developed by the institute and start your academic career.

- Engineer: learn all you need to know about working with industrial applications of lasers and developing orders for industrial clients.

- Entrepreneur: get the skills to turn your invention into a startup.

- Artist: learn to combine laser technologies with the field of art & science.

“At the institute, our students get every opportunity to study photonics and laser technologies. They can implement any idea they have: we invite them to join our grant-supported research and industrial projects and we also organize minor courses in soft skills and entrepreneurship in case they want to launch a startup in the future,” says Maksim Sergeev, a senior researcher at the institute and the head of the Laser Technologies Bachelor’s program.

Maksim Sergeev. Photo by Dmitry Grigoryev / ITMO.NEWS

Regardless of their chosen track, all students receive training in engineering and technology. In their first two years, they are introduced to the institute’s laboratories and their future specialization, while in the final two years they attend specialized courses and conduct research. This approach equips students with experience of working with real-life laser equipment, as well as gives them the chance to contribute to actual industrial orders. Master’s and PhD students supervise the fledgling researchers on this path.

Master’s program. There are three in-depth specializations for Master’s students within the Laser Technologies program:

- Laser Micro- and Nanotechnologies: here, the focus is on the physical and technological foundations of laser technologies and their various applications.

- Laser Biomedical Technologies: this specialization is for those interested in laser surgery, aesthetic medicine, dentistry, ophthalmology, and other biomedical applications of lasers.

- Industrial Laser Technologies: starting from their second semester, students in this specialization will be working on applied solutions. They will meet their potential employer before graduating – their technological solution will make up the core of their graduation thesis.

Students can look for industrial partners of their startups, internships, or job opportunities by attending public talks organized by the institute. There, students will get the chance to discuss their ideas and projects with the institute’s researchers and industry representatives.

A prototype of a wireless power transfer system. Photo courtesy of ITMO's School of Physics and Engineering. Credit: Stepan Likhachev

Graduates of the program can work as engineers, laser equipment operators, engineers of laser materials processing, and others.

PhD program. Master’s graduates can also continue their studies at the PhD level within the following specializations:

- Photonics

- Laser Physics

- Optical and Opto-Electronic Devices and Complexes

Together with the institute’s Bachelor’s and Master’s students, PhD researchers develop the existing grant projects and launch new ones. They also have the opportunity to receive support and expert feedback on their research at special events. One such example are Ask Veiko seminars:

“At these meetings, supervisors and experts (from ITMO and other organizations) discuss a student’s project and offer recommendations on how to improve it. For instance, they try to work out a way to prove a hypothesis or explain why a particular result was produced. Moreover, these events keep our students within their thesis schedule, so that they can be sure that they are heading in the right direction,” says Yaroslava Andreeva, deputy head of the institute, who coordinates PhD students.

Yaroslava Andreeva. Photo by Dmitry Grigoryev / ITMO.NEWS

The institute’s research areas

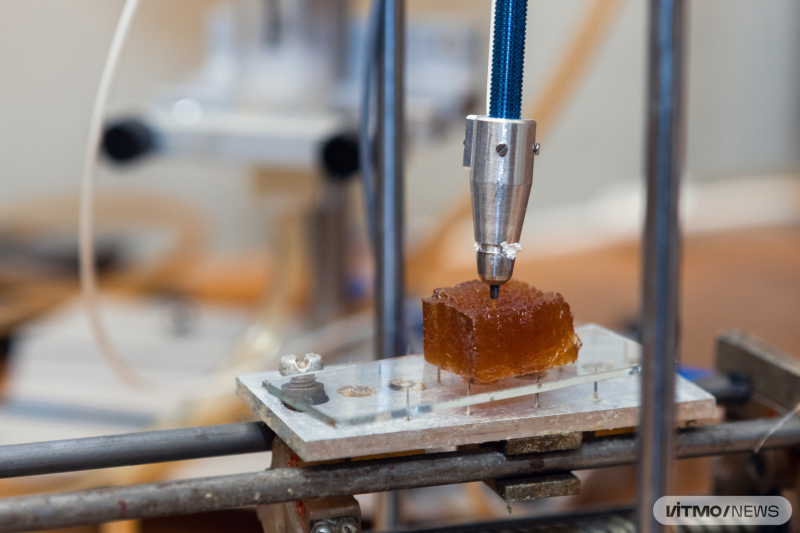

One of the teams at the institute is headed by research engineer Yulia Fyodorova. In collaboration with the N.N. Petrov National Medicine Research Center of Oncology, the group is working on targeted drug delivery for photodynamic therapy at the Laboratory of Biomedical Laser Technologies. This is an efficient method of delivering photosensitisers used to treat mycosis (fungal infections) in skin and nails. Antifungal ointments cannot always reach the source of the illness, while pills can have various contraindications. The laser-based treatment can be a great alternative: first, micropores will be made in the affected tissue; then, they can be filled with a drug, which will afterward be delivered to the source of the infection when subjected to laser radiation. According to the team behind the project, this proposed new method has almost no contraindications, while also being capable of treating mycosis within 3-4 sessions.

Other projects of the lab include laser hair extension technology and combining biotissue of mucus membranes to protect tissues in the mouth from infections after surgery.

Read also:

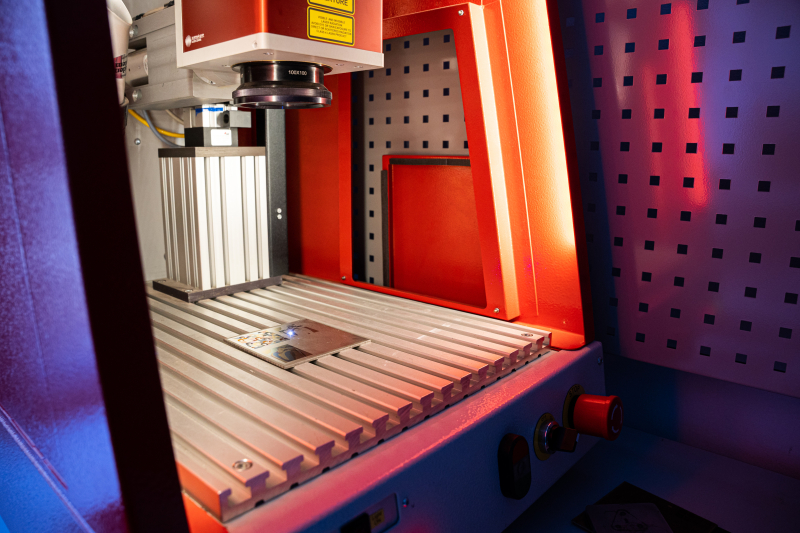

At the Laboratory of Industrial Laser Technologies, the researchers develop technologies for functional surfaces in construction and functional materials. When subject to laser radiation, materials can acquire additional properties – they can be made hydrophobic, hydrophilic, or a mixture of these. This method can also be used to develop microfluidic systems, turn metals corrosion-resistant, prevent glass from steaming over, and much more.

Moreover, the researchers were able to create a technology to produce titanium implants that are biocompatible and have antibacterial properties, thus preventing inflammation and implant failure. The new implants are already being produced by the company Lenmiriot. In the future, the technology can also be applied for hip bone and skull implants.

Researchers from the International Research Laboratory for Micro- and Nanotechnology Lasers have also contributed to the development of the new implants. Within an international team featuring researchers from Australia, Germany, and France, they determined the properties that have to be created in the new implants, as well as their surface structure. They also demonstrated the effects of laser radiation, chemical composition, and surface geometry on bacteria found in biological tissues. As a result, the team presented their own implant surface design imitating bone tissue structure.

Apart from such applied studies, researchers at the lab conduct fundamental research. For instance, they determine the properties of laser plasma created at the interface of a translucent and an opaque medium and find its applications in processing translucent materials.

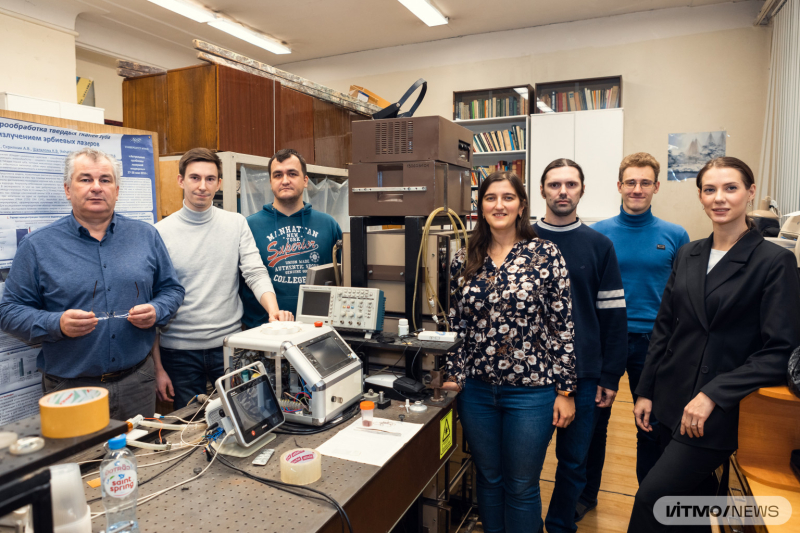

Yulia Fyodorova with the team of the Laboratory of Biomedical Laser Technologies. Photo by Dmitry Grigoryev / ITMO.NEWS

How to develop your own project

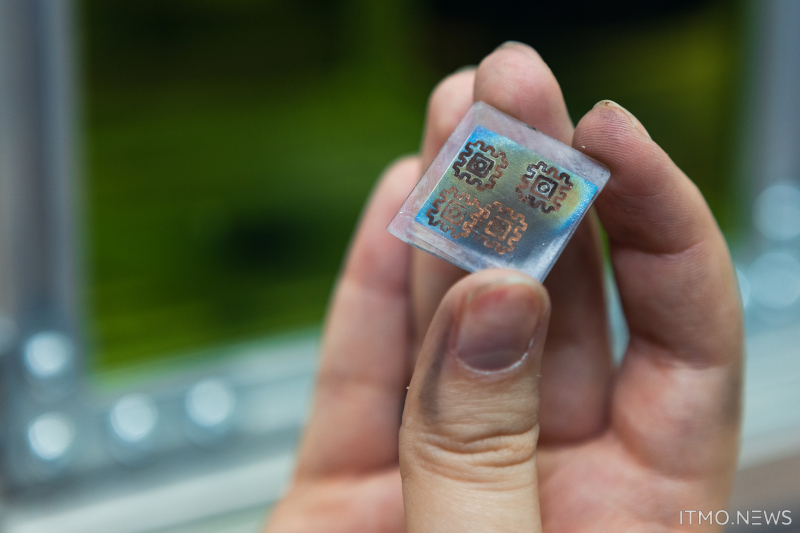

There is room to grow for those students who wish to develop their own projects, as well. For instance, last year PhD student Ekaterina Avilova won a million ruble grant in a student startup competition. She is developing her study on a new laser-induced copper deposition method from deep eutectic solvents, and will now be working with the team of EvtectMed startup on electronic circuit boards. The project can find its applications in flexible electronics, chemical sensors, and RFID tags.

Read also:

The result of laser printing: a square gear and an SPE element fragment. Photo by Dmitry Grigoryev / ITMO.NEWS

Evgeny Prokofiev, a second-year Master’s student, is working on a technology for printing holographic trademarks on steel, which will help protect various devices from forgery. Such prints will be more secure and durable than holographic stickers now used in their place. Evgeny is planning to defend his thesis as a startup and then offer his idea to industrial partners.

Students can turn to the institute’s center for technology transfer to put their ideas into projects and find business partners. Those students who don’t have an idea yet will have the opportunity to join a team that the center will put together to solve an existing problem of one of its business partners.

“Our goal is to help our students walk through the process from a technology to a product that can be implemented in the industry. That’s why startup teams from the institute don’t only join ITMO Accelerator but also attend free training on launching and developing their startups that we organize. We tell them how to find an idea, manage a team, create a business plan, and much more. We are also ready to help students with legal and financial issues they face when starting their businesses,” shares Galina Odintsova, the head of the institute and a senior researcher.

Galina Odintsova. Photo by Dmitry Grigoryev / ITMO.NEWS

Vadim Veiko also believes that dreaming is just as important as studying or developing projects. Here, at the Institute of Laser Technologies, any dream can come true:

“My life has taught me that if you keep dreaming, your dreams will come true. I once dreamt of painting with lasers. I didn’t know how to approach it at first, but then it came to me that it can be done by local laser-induced oxidation of a metal surface. In other words, we can create films of oxides that will produce interference colors. And so the laser brush came to be. That’s why the most important thing is to keep dreaming – and, of course, take action to make your dreams come true!”