Tell us about the Asia-Pacific Youth Forum on Digital Innovation and Entrepreneurship. What activities were included in the program?

Anton Kulikov: The forum was dedicated to youth entrepreneurship, opportunities for starting a business in Taiwan, and information technologies. Much discussed were the topics of whether it is worth it to branch out to Taiwan business-wise, why move there, and what the country offers to budding entrepreneurs who have just graduated from university and are now considering different options for running their business overseas. In the bigger picture, though, the forum organizers’ main aim was to attract to Taiwan as much international young talent as possible, so that they could unlock the business potential of the place. Taiwan’s market has its own specifics; it’s a highly industrialized economy, that’s why plants and factories are the top priority here. But these differ from your usual industrial objects: ‘smart factories’ are becoming more and more widespread. We discussed it at the forum as well. In a smart factory model, all production elements are united in one complex digital ecosystem. Unlike their ordinary counterparts, smart plants are equipped with IoT sensors and sophisticated information systems which can process the sensors-obtained data in an intelligent way.

The forum lasted for three days and included many international speakers, though the majority represented the Taiwanese business community. Also present were the local government officials. Participants came to Taiwan from all over the world, mostly Asian countries. There were some 70 people attending in total.

During these three days, we talked about entrepreneurship and popular business activities to explore in Taiwan. Their market is so distinct that it’s almost mind-blowing. For example, in the video-game section, there were games I’d never seen in Russia or anywhere else. But despite these idiosyncrasies, Taiwan welcomes foreign entrepreneurs with open arms. They really do offer great conditions for starting a business; market newbies enjoy lower taxes and many other economic perks. The public sector is open and willing to engage in the dialog with the business community.

Only three participants from Russia were given the opportunity to attend the forum. How did you become one of these three?

Anton Kulikov: Organizers had several formal requirements: only students or graduates of a specific university who were under 30 years old, able to speak English, and had experience in the field of startups, could be considered for participation. They extended invitations to some universities, ITMO included. As our company is a resident of ITMO’s Technopark since its very beginning, we were approached with an offer to participate. I had to submit a CV indicating my fields of activities and what our startup is about. Organizers selected participants based on how similar their specializations were to the topics discussed at the forum. They were also interested in people who could launch their business in Taiwan.

Starting from 2011, VISmart has been developing technologies in the field of semantic processing of data. Any recent changes in the company’s profile?

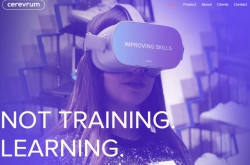

Yuri Emelyanov, CEO and co-owner of VISmart: As of now, our company explores two different fields: semantic technologies and the development of industrial simulators, including both 2D panels and 3D VR-model simulators. Two years ago, we started collaborating with a Norwegian company Pale Blue, which led to the creation of a semi-independent department within VISmart. Anton is the project lead for this department.

Anton Kulikov: Using VR glasses in manufacturing is an emerging research field with lots of potential. Everyone I spoke to at the forum was really excited about it.

All the projects we’ve been developing in cooperation with Pale Blue are about simulation of manufacturing activities. We mostly work with divers who conduct their work underwater, laying oil or gas pipelines on the seafloor. We make it possible for them to practice the operation in our systems before the actual dive takes place. We run several projects, some of which simulate a specific scenario like laying a pipeline or welding the two ends of a pipe together in underwater surroundings.

Yuri Emelyanov: Today, Pale Blue’s main target audience are diver teams who could benefit from these solutions in several ways, including economically. When divers are brought to an object they’ll work on, it takes them some time to understand their new location and plan on how to conduct leverage and where the pipes should go. A whole ship is employed to send a couple of them to an object. Before taking a deep-water dive, they usually spend some time in a diving chamber. When there, they could use our device and familiarize themselves with their surroundings before going out there. This would save them time, and their contractors’ money.

Anton Kulikov: One of our simulators was singled out as the only software-based simulator approved by IMCA (International Marine Contractors Association) for training and certification of personnel. This simulator in question was designed to train future diving supervisors.

It consists of two panels equipped with a range of consoles, devices, sensors and switches needed for supervising both the diving process and underwater works. Supervisors interacting with these panels have many aspects to monitor, for example, that the breathing gas mixture supplied to the divers is fit for breathing, that their devices get an uninterrupted energy supply, and, crucially, that they stay in touch for the whole duration of their dive. All this is done by one person operating these control panels. Diving supervisors-to-be go through a lot of training, but our simulators can accelerate and facilitate their learning. Before we introduced our solution, they had to practice on-site or using unwieldy training panels which were transported in huge carriages from one place to another. It obviously wasn’t a very portable device. Our simulator, however, comes with two touch screens and an ordinary Windows-based computer, which makes it significantly cheaper than real-world panels replicas.

Do you plan to adapt your industrial simulators for other spheres?

Anton Kulikov: Though diving remains our main focus, we’re exploring new spheres as they emerge. We’ve just branched out to molecular chemistry and are creating prototypes for the visualization of various chemical processes. Another of our new projects is based on developing training solutions for surgeons. You can apply simulators in an infinite number of ways.

Yuri Emelyanov: Process simulation is making headway in many fields as this is an ideal solution for training of specialists or demonstration of products or services that cannot be done in real life because it would be too expensive or dangerous. For instance, our diving simulator allows us to imitate the breakdown of the cable that connects a diver to an air supply. It’s extremely difficult to simulate this scenario in real conditions. Divers have a special set of rules on what to do in such a perilous situation, and with the help of our simulators, they can now practice performing these life-saving instructions.

How was your startup received at the forum and was it useful in any way?

Anton Kulikov: Many participants expressed a real interest in our work; all of them come from different fields, some have already established themselves in the business community. Partaking at the forum made me think of new applications for our products and new fields we can explore in the future; for example, I’d never considered promoting VISmart solutions to Taiwan’s smart factories were it not for this event. It just so happened that some of the speakers I met there work in this sphere, which could be very useful for our company. There is a lot of potential for us in Taiwan in general as many businesses opt for building their plants here.

What are your plans for the near future?

Anton Kulikov: Back in Taiwan, we managed to establish useful contacts with a range of entrepreneurs that were especially interested in what we do. Some of them work in IoT and heavy industries. We also met a Nigerian businessman who develops buildings that are protected against natural disasters specific to a particular area. We’re looking forward to working with our new partners to create new solutions in different spheres.