The robot has a loading capacity of five kilograms. It is a bench robot widely used in the industry for sorting small parts of all kinds – especially, in pharmaceuticals and medicine.

This machinery is a perfect solution not only for meeting engineering challenges and exploring the work of the device but also for testing various research hypotheses.

ITMO’s International Laboratory of Geometrical Methods in Control and Application uses the platform to test algorithms of complex trajectory analysis. Such algorithms allow robots to perform high-precision movements along a curved pattern, for example, reproduce a drawing from a graphic file or write a greeting – “¡Hola!”

As the robot’s software remains a close source, the ITMO team came up with a kind of a translator – a software layer for adapting complex trajectory commands to the robots’ language. The entire path is described not as a set of points in space that the robot must repeat but as a set of functions, each of which controls only a small segment of the path. The in-depth analysis of the trajectory results in a smooth and continuous motion of the device.

The developed algorithm can not only be used in robotics but also adapted for various applications.

In addition to training, the robot cell is also applied to test grippers developed at ITMO as part of research and contractual work with industrial partners. Several manufacturers are already integrating these solutions into their production, and articles with this research are published in peer-reviewed journals.

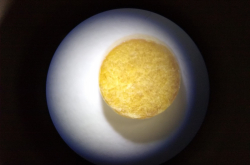

The gif below shows a prototype of the Ukhvat gripper, which was created to test the method of synthesis of multi-link mechanisms of сlosed kinematic chains.