When choosing food at the store, we typically consider its expiration date. However, it doesn’t always reflect the product’s actual condition – a product can expire both sooner or later than expected. What’s more, during transportation, hazardous bacteria such as salmonella, listeria, or staphylococcus can develop in the product. All of this makes it difficult for consumers to decide whether a product is safe based on its appearance or smell alone.

With smart packaging, it’s possible to track a product’s actual expiration date. Such packaging can be used to monitor the product’s condition and any changes that happen inside or outside the packaging; for instance, if a product was refrozen several times or if the packaging was damaged.

“Many researchers are developing smart packaging, but the question is how do you make it smart – do you use sensors, indicators, or biosensors? Importantly, any smart elements you use should be cheap to produce, safe, and easy to use. That’s why we decided to apply quantum dots placed in polysaccharides; these materials are biocompatible, non-toxic for humans, and easy to synthesize. Thus, we used them to create fluorescent indicators. In lab tests, we observed that the indicators react to hydrogen sulfide produced during the decomposition of protein products, such as meat, chicken, fish, or seafood. The higher the concentration of hydrogen sulfide, the dimmer the indicators glow under UV light. This means that the product has gone bad and shouldn’t be consumed,” explains Elena Nazarova, the head of the project and head of a laboratory at ITMO’s Research and Educational Center of Chemical Engineering and Biotechnology.

Elena Nazarova. Photo by Nikita Seliverstov / Megabyte Media

Scientists at the BioNanoTech lab (part of ITMO’s SCAMT Institute) suggest placing fluorescent indicators on the inside of transparent films that cover the packaging. This way, carbon dots won’t contact the product, but will react to the substances released by bacteria inside the packaging.

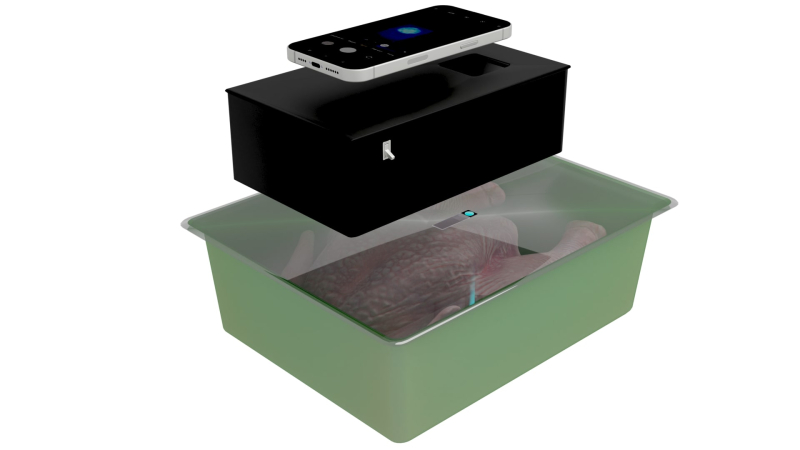

To make it possible to assess a product’s condition outside a lab environment and without professional equipment, the team has developed a prototype of a special module for smartphones with a built-in UV LED. When the module is placed above the packaging, the UV light hits the transparent film with the indicator. Then, the smartphone’s camera captures the optical response of the indicator, while a special program on the computer analyzes how much the intensity of the fluorescence has decreased.

In the future, the researchers are planning to make the module more compact so that it could be placed in stores near the products. Moreover, they will develop a special app that, in just a few taps, would inform consumers if the product they picked is fresh.

Last summer, the team became one of the winners in the second season of the reality show Passion for Grants, in which scientists from around the country compete for Russian Science Foundation grants. The team from ITMO secured 6 million rubles to develop their fluorescent indicators. In 2024, the foundation supported 641 projects by young scientists from the total of 3,000 grant applications.