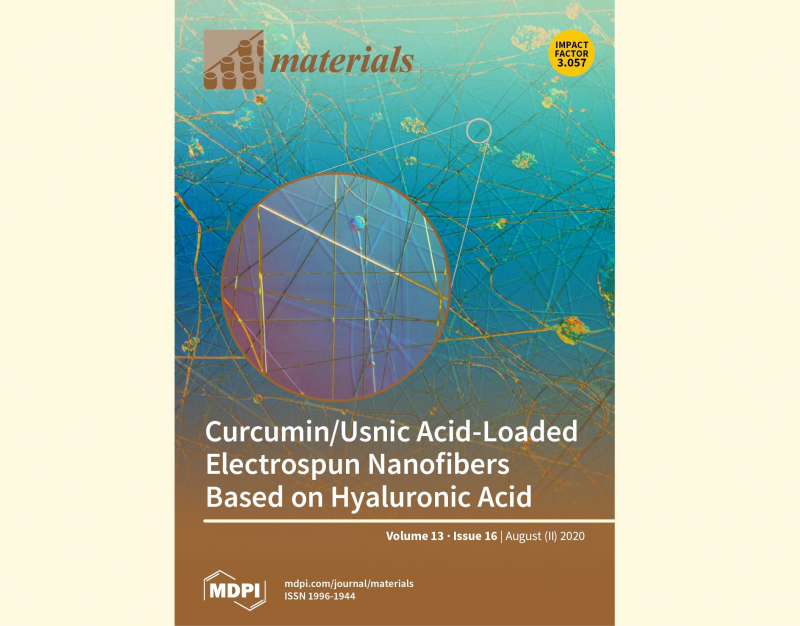

The new polymer nanofiber was created as part of Petr Snetkov’s PhD project, supervised by Prof. Mayya Uspenskaya, head of ITMO’s International Scientific and Research Institute of Bioengineering. The paper presenting the results of the project was published in Materials, and was chosen by the MDPI publishing house to be the cover of its 16th issue containing over 200 publications.

Hyaluronic acid is actually vital for an organism: it is a part of not only cells but also of pericytal and intercellular spaces. That is why medical treatments based on it are absolutely biocompatible and biodegradable. Even more importantly, it is absolutely neutral to the human immune system. Curcumin and usnic acid, however, are powerful immunostimulators and antioxidants – but their bioaccessibility is extremely low, as they are almost insoluble in water.

The combination of hyaluronic acid, curcumin and usnic acid has a unique complex of properties: antitumor, antioxidant and antiseptic – and with that it is completely biocompatible and biodegradable.

As conceptualized by the authors of the paper, such nanofibers acquired from polymer solutions by electrospinning can be used to produce wound dressings for treatment of melanomas, burns, ulcers, eczemas, and neurodermitis, which is a rather promising and important field in medicine, as, for instance, there is still no functional treatment for melanoma. The developed method of introducing biologically active substances into a polymer matrix can also be applied in creating nanoparticles for targeted delivery of treatment to an affected organ.

The main scientific breakthrough is that it is the first time that natural hydrophobic additives could be integrated into a matrix of hydrophilic hyaluronic acid. It has to be noted that biologically active substances were produced without catalysts, the majority of which are highly toxic.

“The problem with hyaluronic acid is that it isn’t soluble in organic liquids, but only in water. And solutions based on water are hardly susceptible to electrospinning due to slow water evaporation, high viscosity and conductivity,” explains Petr Snetkov, co-author of the paper, a PhD student at ITMO’s Faculty of Applied Optics and engineer at the International Scientific and Research Institute of Bioengineering.

Researchers can overcome this obstacle by applying various methods. For instance, by using modifying polymers, such as polyvinyl alcohol or polyethylene oxide.

"There is a significant number of publications on this topic. But the problem is that the amount of hyaluronic acid in such systems is substantially lower than the amount of modifying polymers, which makes us question their efficiency. Another method is using co-solvents, such as dimethylformamide. This is a rather toxic substance that is inapplicable for medical purposes," adds Petr Snetkov.

The authors of the paper used dimethyl sulfoxide as a co-solvent, a wide-spread medical treatment for external application. This substance made the produced nanofiber not only completely safe to use but also added antiseptic and anesthetic effects.

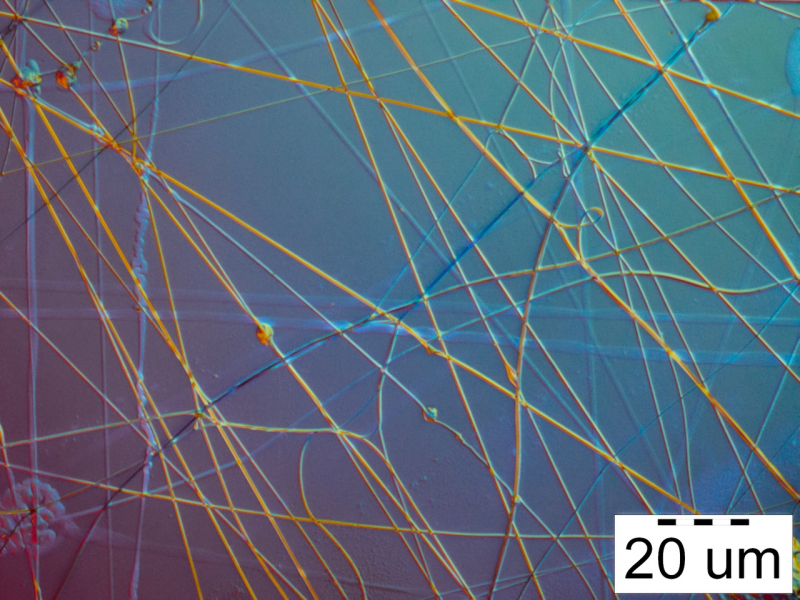

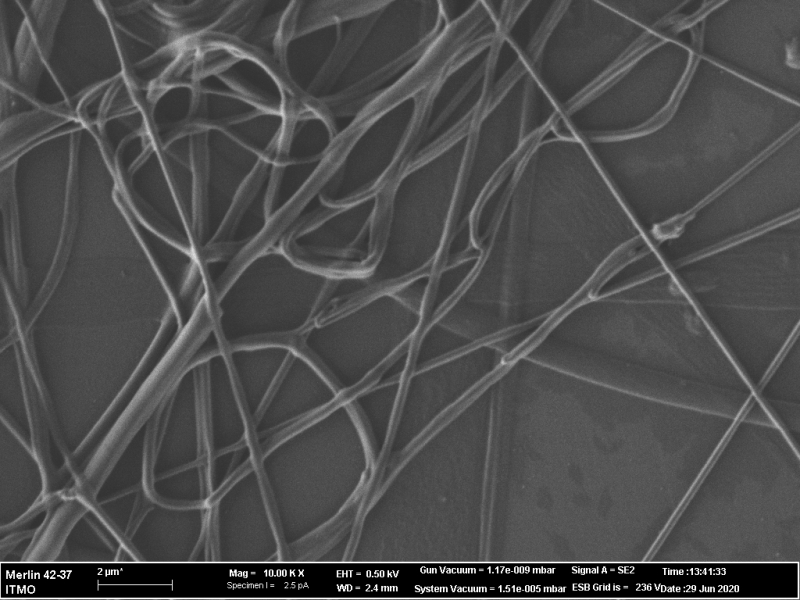

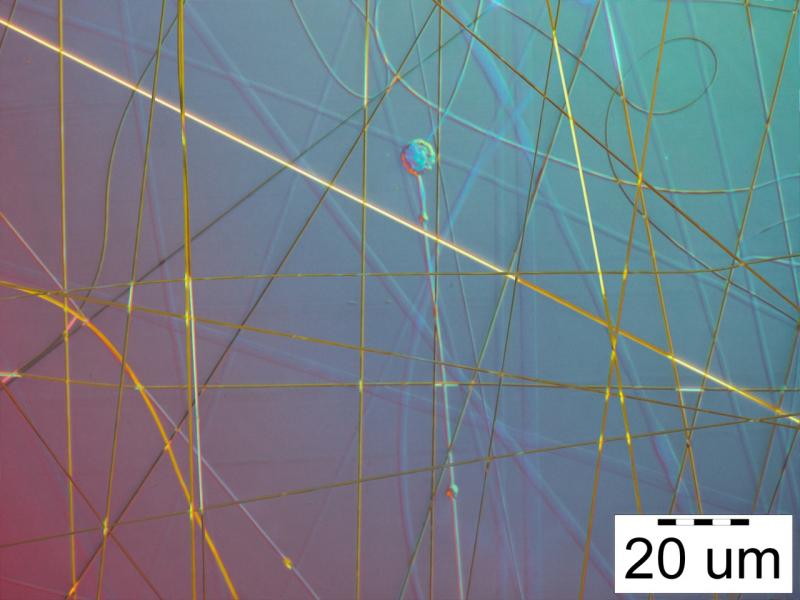

During this project, it was proven that morphological characteristics of pulled fibers can be regulated: if the voltage of electrospinning changes, the fibers can get thinner or thicker. By choosing different concentrations and molecular masses of polymers in the mixture, we can acquire not only nanofibers but also nanoparticles that can be introduced into the blood flow to be used for targeted treatment delivery.

“Thanks to the fact that hyaluronic acid is negatively charged, a lipid coat will form around it that can clog minute blood vessels. We have produced particles around 200 nm in size. When we presented this work at the conference for young scientists “Contemporary problems of polymer science” last year, we received a lot of feedback, including those about the possibility to use these particles for intravenous administration,” says Svetlana Morozkina, co-author of the paper, associate professor at the Faculty of Applied Optics and an engineer at the International Scientific and Research Institute of Bioengineering.

The researchers are currently focused on developing wound dressings but they underline that this technology can be used in various fields of application – for instance, in production of artificial blood vessels and as a carcass for growing artificial tissues and organs.

The project is supported by the 5-100 and RFBR grants for PhD students, the latter of which is for research of fiber materials based on biopolymers. According to the scientists, however, pharmaceutical companies are also interested in it.

Right now, the project is entering its second stage, which means improving the method and technology, as well as selecting optimal environmental conditions that would ensure the production of nanofibers with a set of exploitation properties, such as, for instance, porosity.

The researchers will also focus on scaling this technology for industrial manufacturing. Later, the project will enter the stage of in vitro testing – first on cellular and then on animal models. It is planned to complete the project and introduce it into clinical practice in two years.

“Later, we are planning to, naturally, widen our research by analysing the fiber’s physico-mechanical characteristics and the kinetics of active substance release. It’s important to ensure stable performance: if we consider wound dressings, then they have to work under any, even the harshest environmental conditions, including those of military action. An additional field of research will be introducing other biologically active substances, because the strategy of implementing hydrophobic agents into a matrix of hydrophilic polymers has already been designed and tested,” concludes Petr Snetkov.

Reference: Petr Snetkov, Svetlana Morozkina, Roman Olekhnovich,Thi Hong Nhung Vu, Maria Tyanutova, Mayya Uspenskaya. Curcumin/Usnic Acid-Loaded Electrospun Nanofibers Based on Hyaluronic Acid. Materials 2020, 13(16), 3476, doi.org/10.3390/ma13163476