What are your research interests?

I work with physical, colloid, and electrochemistry, and a little bit with biotechnologies. Colloid chemistry is integral for all of these fields. The majority of my projects focus on self-assembly in liquid/liquid or liquid/air interfaces. Colloids are mixtures of solid nanoparticles dispersed through a liquid, so this can be said about many everyday things. Take milk, for example, where water, fat, and protein are combined in a way that we treat it as a homogenous liquid. I also have a background in materials science, so part of my activities in industry and academia were connected to chemistry of new materials: I worked in two startups, where I developed titanium dioxide for solar cells and materials for 3D printing.

How did your nearly 10 years of international experience in Germany, Switzerland, and China influence you?

I believe my experience in Switzerland has mostly shaped me as a researcher. In my seven years there I defended my PhD thesis, worked as a postdoc at EPFL, and joined a startup. Naturally, I was impressed by the high standards of lab maintenance and management: everything is clean, the rooms are spacious, and you have access to any equipment. At EPFL, all processes run at workstations: a research installation, a computer, and a table for preparing samples. Our new lab at ITMO will implement a similar system.

When I was graduating with my PhD, I had to decide whether I’d be staying or moving to another country. Back then, I considered Russian universities, including ITMO. It was about that time that I got in touch with Ekaterina Skorb, who used to work with Prof. Helmuth Möhwald, our mutual acquaintance. A little later, Ekaterina suggested I apply to ITMO Fellowship.

In September 2021, I moved to China to work at the then newly-launched Shenzhen MSU-BIT University. There, I taught materials science to Chinese students and supervised seven Bachelor’s students theses. There, I gained valuable communication skills, and I believe this experience prepared me for what I am doing at ITMO now.

Eugene Smirnov, Timur Aliyev, and Ekaterina Skorb at the award ceremony of the Blue Sky Research contest. Photo by Dmitry Grigoryev / ITMO.NEWS

Tell us about your research at ITMO.

As an ITMO Fellow, I am running a colloid chemistry project with my group Chemotronics and Interfaces. The essence of our work is reflected in the name of the group: interfaces are borders between two systems and chemotronics is a field that studies electrochemical processes in the electrode/electrolyte interface driven by electric current, as well as various devices using this principle. Chemotronics is not unlike electronics, but it runs on molecules that can be oxidized and deoxidized. One popular chemotronic device is a supercapacitor, the power cell at the core of every electric car and engine. For instance, Tesla cars have a battery and supercapacitors that quickly transfer its energy to its wheels and engine.

Another example is a memristor, an electrical element that regulates its resistance depending on the electric current that went through it. We can train memristors like physical artificial neurons, effectively assembling a neural network without using any software. Currently, we are finishing an article on this topic.

Starting from September 2022, in collaboration with other researchers from ITMO and with support from the Russian Science Foundation, we have been developing a project on self-assembly of gold and silver nanoparticles in the liquid/liquid interface as a platform for Raman scattering method. Within this initiative, we produce thin films of ordered nanoparticles that we can transfer to various surfaces, enriching them with different functional properties. For instance, gold nanoparticles can be used to modify various surfaces, as well as manufacture optical filters and liquid mirrors for astronomers.

Sounds like a dream. Could you give us a real-life practical application of this research?

When I get asked this question, I think about Canadian scientist Ermanno Borra, who dreamed of putting a liquid mirror made of nanoparticles on the Moon’s surface. In 2007, he described his daring alternative to the Hubble and James Webb telescopes in Nature. It takes 3.5 years of polishing to produce one mirror for the James Webb Telescope, which then has to be linked to the others and delivered to the orbit. The mirrors in this telescope have the average roughness of 10-15 nanometers, which allows them to “see” distant galaxies. Borra had a different approach: instead of delivering glass to the orbit, he suggested lifting a special liquid and then locating nanoparticles on its surface. If we spin it, turning it into a parabola, it will shape into a perfect telescope once it freezes. According to Borra’s estimates, this technology would’ve been 50% cheaper than launching the James Webb Telescope.

The main mirror of the James Webb Telescope. Credit: NASA

But there are other applications as well?

Yes, our other area of research concerns MXene titanium carbide, which is a 2D material that also can be assembled in the liquid/liquid interface. We turn it into thin films that can be used as humidity and tactile sensors, as well as detectors of gasses and other substances.

We also experiment with graphene, a material that became very popular in recent years, which is very tricky to produce films from. One of the standard production methods is vacuum filtration: a solution passes through a filter with very small pores so that a film remains on the filter. Such films are then layered upon each other, resulting into a graphene-like material. Instead of layering them, we could also place these films side by side in the liquid/liquid interface. If we learn to produce such films and transfer them to silicon, we will be able to make sensors, microelectronic and hemotronic devices, including memristors.

Credit: ITMO University

What are your objectives for the ITMO Fellowship program?

I hope we can develop a system that is applicable not only for gold particles, MXene, and graphene but also for assembly of other materials. We would then patent the system, and make a spinoff to make the technology self-sufficient. For instance, we could provide services to other researchers who want to produce films from nanoparticles of other materials.

Another direction we would like to go in is biotech and colloid systems, such as food products – smoothies, dairy products, and more. We want to come up with new approaches to the food industry. For example, colloid chemistry can help us hide the taste, increase product yield from raw material, or locally change pH and other properties that would improve the product.

Lately, plant-based protein is becoming more popular as an integral part of our future diet, because it’s much more sustainable to grow soy beans, peas, or sunflower than raise a cow. However, there are some challenges in plant-based protein production, one of them being the use of such substances as saponins, tannins, phenols, and polyphenols, that negatively affect the taste and color of final products. One of the projects I am involved in uses colloid and interface chemistry to mask the taste of such products. This technology will allow us to add protein to a wide range of products, making them tasty and nutritious, as well as change its carbohydrates, proteins, and fats ratio. In particular, we are planning to produce capsules with protein that would deliver it straight to the stomach, relieving our consumer of the need to feel its taste.

As you see, our research can be used to produce liquid telescope mirrors, as well as to improve recipes of food products, all thanks to colloid and interface chemistry. In the future, we are hoping to be able to model the behavior of different colloid systems.

A new student-centered lab has recently launched at the Infochemistry Scientific Center. What opportunities does it offer students?

I teach physical chemistry at ITMO and currently I am trying out different approaches. One of them is teaching through lab practice. Moreover, we are planning to collaborate with ITMO’s Faculty of Biotechnologies. I hope that by the end of the year, most of my students will have a paper they will submit as their graduation thesis.

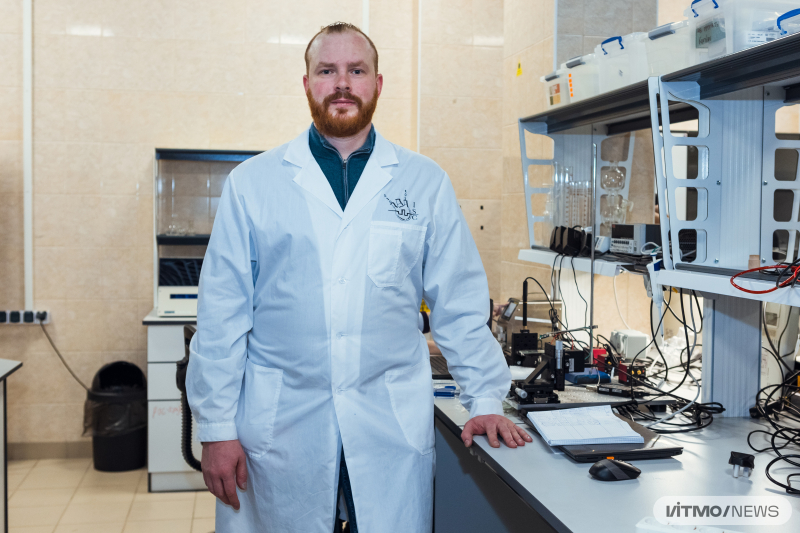

The new lab at the Infochemistry Scientific Center. Photo by Dmitry Grigoryev / ITMO.NEWS

Read also:

ITMO’s New Lab To Develop Next-Gen Sensors and Associated Technologies

ITMO Scientists Win the First Blue Sky Research Innovative Scientific Projects Contest

What do you think about popular science?

There are two approaches to it. The first one is when we get down to layman’s terms and explain something simplistically. That’s done by 80% of science communicators. It might be good, it might attract an audience. But there is also another way: bringing the audience to your level. Many people follow the path of maximum simplicity without giving their audience a chance to get an overview of the problem in question. This can give your audience a dangerous feeling of expertise in the field after they’ve understood the mere basics of it. Remember the multitudes of virus experts online during the pandemic? It was like a planet-wide Dunning-Kruger effect.

That’s why I try to follow the second approach. Science communicators should present research in a way that stimulates their audiences to get deeper into the topic.

It might put someone off – after all, something might seem too difficult to understand.

Well, generally, life is complex and difficult to understand, too. You won’t learn anything by always choosing the easiest path without any challenges. In this sense, I like the format of TED talks – they always inspire you to google a little more, get into a new field.

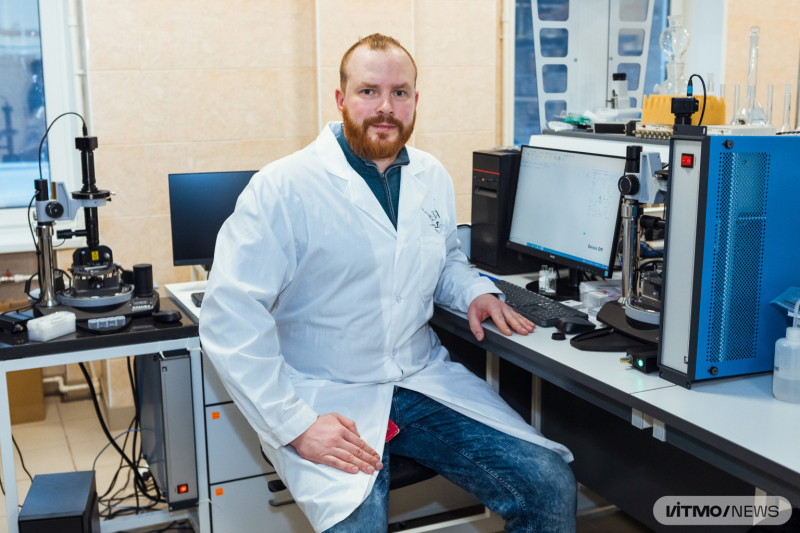

Eugene Smirnov. Photo by Dmitry Grigoryev / ITMO.NEWS

Did you take the same approach in your own life?

I studied at the Advanced Educational Scientific Center, a boarding school and a faculty of Lomonosov Moscow State University (MSU). Back then, we didn’t have the Unified State Exam, so after graduation we could receive recommendations to be enrolled at one of the university’s faculties. I could choose between chemistry and materials science. As I imagined, most of my classmates would opt for chemistry, which didn’t seem appealing to me. Moreover, the curriculum at materials science was promising to be challenging – so that was what I chose to do. In 2011, I graduated with honors and got into a PhD program at MSU. After a year of studies, I moved to Switzerland. Then, in 2019 I came back to Russia, landing jobs at the university and a startup. And then the pandemic struck. In the middle of 2021, I got the offer to work in China. I thought, why not? This was my experience before ITMO Fellowship, which, too, is something new and unique, as ITMO is nearly the only university in Russia with such a program. So I believe I can say that my principle in life is to get into curious and challenging circumstances.

What are your hobbies?

I do a bit of everything – skiing in winter, gym workouts in spring and fall, and traveling in summer. Sometimes I dabble into 3D printing, for instance, I printed Lakhta Center in 2021. Maybe it was a sign I’d move to St. Petersburg. Recently, I got into restoring old video footage, which combined well with the course on science journalism at ITMO. I also love traveling. Not chilling at a hotel, but roadtripping – that’s how I’ve done most of my European trips. Once I did try visiting the south of Russia to sunbathe at the beach but ended up touring vineyards. As I’ve recently learned, last year’s Congress of Young Scientists saw a Russian wine exhibition by the Kurchatov Institute – they apply big data for line breeding to improve crop yields and biotechnologies for pest control. So I happened to be two years ahead of this trend.