What is your background? What did you specialize in for your Bachelor’s degree and how did you get into ITMO?

As a Bachelor’s student, I majored in mechatronics and robotics at the Scientific Center for Robotics and Technical Cybernetics of Peter the Great St. Petersburg Polytechnic University. Starting from my third year of studies, I started working part-time at the student design center. I spent three years at the center organizing a robotics cup for school and university students. At the same time, we developed various robotics devices, including building blocks for children and full-scale mobile robotics platforms to study computer vision and robotic control systems in practice.

In 2020, I enrolled into a Master’s program at ITMO and got the chance to participate in a joint project with the Sberbank Robotics Laboratory. Working there, I earned a good salary and took regular trips to the lab in Moscow to present interim results. I have successfully defended my Master’s thesis with this project and decided to develop this topic as a PhD student.

Why did you decide to enroll into ITMO and not another university?

ITMO’s Master’s programs have one winning aspect – they offer specializations, which isn’t a thing at my first university where everyone majoring in robotics studies the same courses regardless of whether they specialize in programming, electronics, or engineering. At ITMO, on the other hand, programmers study their own sets of subjects, while engineers like me study design and learn to use optimization algorithms to synthesize the kinematics and dynamics of robotic systems.

Isn’t it better to be a broader specialist and have equal knowledge in every field?

If you choose to study all at once, you will learn a little bit from every field but you won’t have deep knowledge in any specific topic, so you are somewhat of a distributed specialist. I wanted to deepen my understanding of a specific subject, because I already received quite a broad education during my Bachelor’s studies – I learned a little bit of coding, electronics, design, and mechanics. For my Master’s I wanted to concentrate on the latter two of this set.

Moreover, it’s just more interesting here at ITMO, there are more opportunities for unleashing your potential. You can study, develop your projects and get paid for your work – and then use these projects for your research publications and graduation thesis. There is no need to split yourself between earning a living and studying, because these two are tied together.

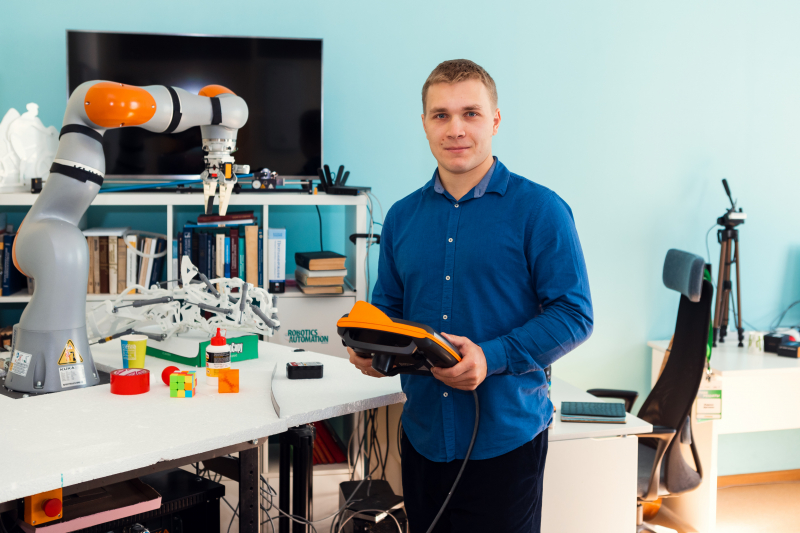

Evgeny Khomutov at the lab. Photo by Dmitry Grigoryev, ITMO.NEWS

Why did you get a job in the industry? Especially as someone having successful collaboration with Sberbank under their belt.

By the time of my graduation, I had already acclimated at the International Laboratory of Biomechatronics and Energy-Efficient Robotics – we have a great atmosphere and a close-knit team. And I already demonstrated that I am capable of working independently. I liked everything here, so I decided to stay.

The main difference between working in the industry and at university is that here we can develop several projects at the same time. This makes you good at multitasking, boosts your ability to switch between projects, manage your time, and build your schedule. When you are a corporate employee, you usually have to focus on just one or two tasks.

Of course, I sometimes think about working at a company. There were moments when I thought of becoming a programmer, when they were in the limelight and there were talks about their high salaries. But after I spent a couple of months coding during my Bachelor’s studies, I realized it wasn’t for me.

Did you ever regret your choice?

I believe that people are responsible for their decisions and therefore regrets don't make a difference, you only get depressed. You have to find something positive about each of your decisions. However wrong our previous decisions might have been, they helped us become who we are.

Tell us more about your current project.

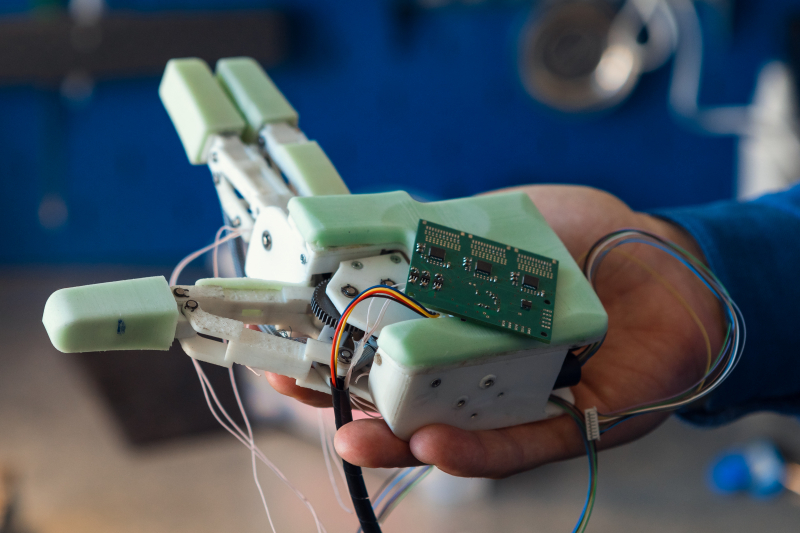

As a Master’s student I designed anthropomorphic gripping devices or, more specifically, a synthesis algorithm for single-drive lever mechanisms. Now I want to upgrade the algorithm and scale it for a wider variety of tasks. I also want to automate it in such a way that someone without a relevant background could use it in their project.

Anthropomorphic gripping device (robotic hand). Photo by Dmitry Grigoryev, ITMO.NEWS

Do you mean that you will make the algorithm available to the public?

The main part of our code is compiled in MATLAB, which means that later we will create libraries for this software package and make it available for other researchers, who will be able to download them and use them when developing their own gripping devices. And they won’t have to get a deep understanding of the topic, the way the code is written, and the variables they need to add. They will only need to put in the necessary parameters, such as the mechanism’s length, the number of its elements, or the type of objects it will need to grip – and the system will generate the optimal kinematics and mechanics for the future device.

This sounds like quite a fundamental project.

It really is a wide-scale and a rather abstract project, but we are implementing it for specific tasks. For instance, as part of our work for the Research Center “Strong AI in Industry,” our laboratory is engaged in generative design technologies. I am responsible for developing methods for automated generation of single-drive mechanisms that will be accessible to non-specialist users.

What goals do you have for the four years of your PhD studies?

My main goal is to become a better version of myself, to bring both my hard and soft skills to a high level. In particular, I am talking about the ability to organize your own work, because no one will do it for you. And I would love to pick up some management skills – to supervise several Master’s students and develop projects together serving as their mentor and tech lead.

Evgeny Khomutov at the lab. Photo by Dmitry Grigoryev, ITMO.NEWS

Do you have a dream project?

As I am engaged in developing gripping devices, I have an idea for a system that will design personalized hand prosthetics. The ones that are now on the market are standardized, so children and adults get the same model, but all of us have different hand geometry. So when a child gets a prosthetic hand that is the size of an adult one, this results in a strong imbalance.

I would like to develop a system that would scan the healthy hand, automatically detect the necessary geometry, and then use this data to design a prosthesis which would mirror the scanned hand. Now it’s just an idea, I am only working on algorithms and automated synthesis methods that could be applied in prosthetics.

I want to make the world a better place, to solve a universal problem by helping people with health limitations. There are companies on the market that develop prosthetics, but it’s very expensive. Whereas we want to create such a system at the university that will make it possible to design prosthetics much quicker – and by accelerating the development process we will also make it a lot cheaper.