What brought you to ITMO and how did you learn about the program?

A friend of mine told me about ITMO Fellowship a couple of years ago. A year later, I decided to apply but, sadly, the competition was too tough and I didn’t get in. However, I really liked the program: it gave me a clear vision of what I was going to do here and what opportunities I’d get. That’s why I decided to try once again in 2020. It was a kind of challenge for me. Eventually, I did get in and started working in October 2021.

Having taken part in similar projects for postdocs and invited scientists worldwide, do you think your experience in Russia was different from what you’d had before?

Before ITMO, I visited the Institute of Experimental Pharmacology and Toxicology of the Slovak Academy of Sciences twice as a postdoc, I also worked at the School of Chemistry and Molecular Biosciences of the University of Queensland, Australia, and the College of Grain Science and Technology of Shenyang Normal University, China, so I have something to compare my recent experience with. I like how well-equipped ITMO’s laboratories are – there was everything I needed for my studies. Besides, I had fewer communication issues here because students and researchers speak English well. When I first came here, my colleagues gave me a tour of the lab and showed how to use the equipment. I knew that I could always ask them and other lab staff for help.

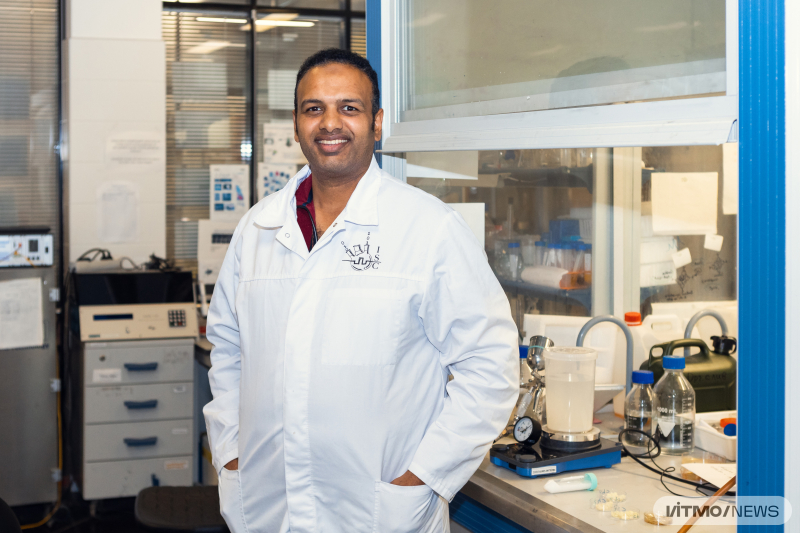

A simple laboratory system to produce homogeneous nanogels. Photo by Dmitry Grigoryev / ITMO.NEWS

Last year, you studied polymeric hydrogel membranes based on antimicrobial and antioxidant proteins for wound dressing applications. Why did you choose this topic?

I’m interested in developing functional polymeric membranes, that is, membranes capable of interacting with other molecules to solve certain tasks. I apply all my expertise to produce a new antimicrobial polymer.

Why? In our practice, we encountered bacterial mutations or, in other words, a developed antibiotic resistance in bacteria. This problem is particularly true for Egypt. Escherichia coli, Staphylococcus aureus, and Staphylococcus haemolyticus, which are some of the most common bacteria in healthcare settings, exhibit a strong resistance to a wide range of antibiotics. Knowing that, we want to come up with next-gen antimicrobial polymers that will fight specific types of bacteria. There are several ways to do that. As my solution, I decided to modify the polymer and turn it into a polymeric membrane, which can be used as wound dressing.

The invention will be especially useful for people suffering from diabetes, as they are more prone to bacterial infections due to high sugar concentrations in blood, which slows down wound healing. The membrane based on antimicrobial and antioxidant proteins should accelerate the healing of wounds and can be used for treating cancer patients, as well.

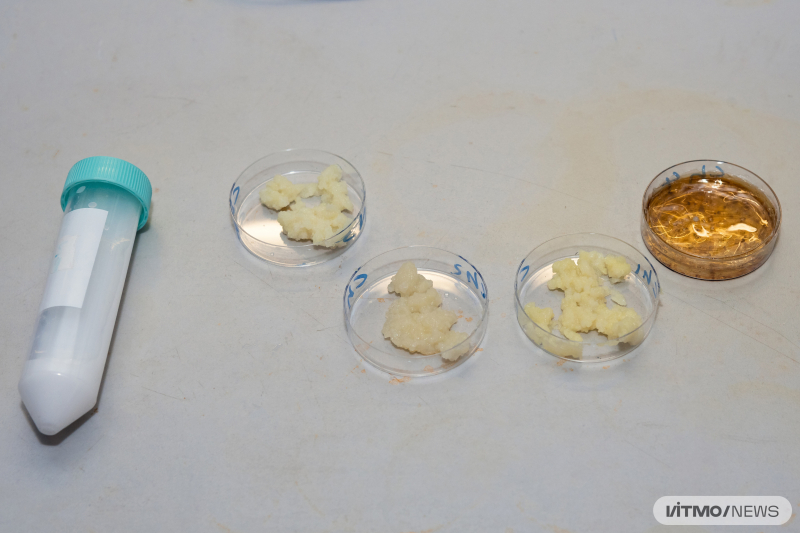

Samples of nanogels made from chitosan and hydroxyapatite. Photo by Dmitry Grigoryev / ITMO.NEWS

What’s the difference between a hydrogel membrane and a band-aid? Aren’t they both used to prevent infection?

Wound dressing products, be it a band-aid or a bandage, traditionally include a sterile cotton sheet that is placed between the material and the wound. This layer, however, doesn’t speed up but rather slows down healing. Whereas a hydrogel membrane creates a humid environment that facilitates cell migration and tissue regeneration.

Also, our product is biodegradable, meaning that it is absorbed into the skin as the wound heals. Thus, patients have no need to constantly change their wound dressing or throw it away like they do with a band-aid.

Read also:

ITMO Fellowship & Professorship Participants Discuss Their Research Projects

ITMO Scientists Develop Novel Hybrid Material to Prevent Post-Surgical Infection

What do you plan to do next?

We’ve developed a prototype and carried out several studies this year, namely tested the membrane for antioxidant and anti-inflammatory effects, as well as ran tests on antibiotic resistant bacteria. As of now, we plan to obtain permission to start testing it on animals and then humans and find a company that would like to help us make it to the market. Later on, we’d also like to extend the list of bacteria that our membrane helps fight.

Moreover, we also began working on a hydrogel with nanoparticles that will help regenerate bones and reduce inflammation. We want to combine a nanohydrogel with calcium and phosphorus responsible for the formation of hydroxyapatite (a building component of bones and teeth) and develop a gel that can be injected at a fracture site.

What else did you do at the university?

Aside from research, I also taught Master’s students. I explained how to write scientific papers and reviews, create designs for studies and other projects, select research methods, conduct experiments, and evaluate results. But it’s also important to let students put what they’ve learned in class into practice. So, I invited several of my Master’s students to join my research on polymeric hydrogel membranes. I assigned them a few tasks, which they successfully completed. This experience helped them gain confidence in their abilities.

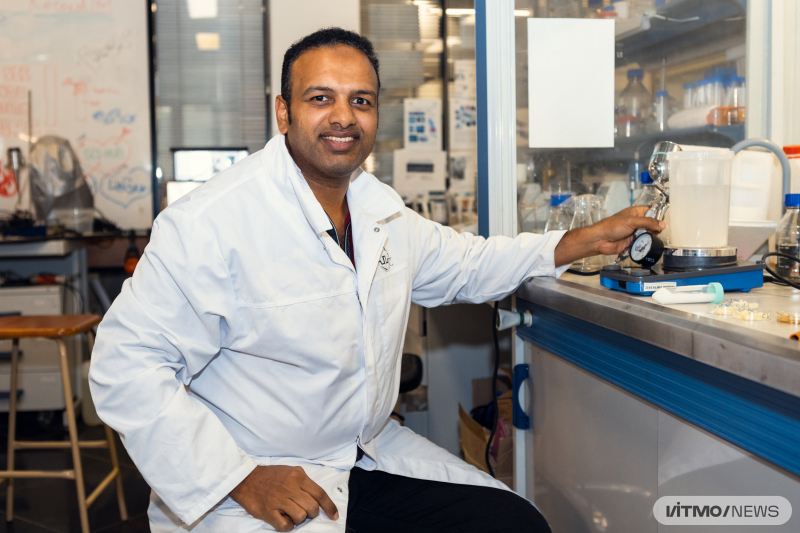

Tamer Abdelrazik. Photo by Dmitry Grigoryev / ITMO.NEWS

What did you like doing outside of work at ITMO?

I took a Russian course. I already know a few words and phrases and can say Как дела? (How are you?) and Я тоже хорошо (I’m doing good, too). I also enjoyed walking around the gorgeous park in Peterhof and traveling to the city center.

What are you going to do next?

After my fellowship at ITMO, I’m going home for a while and then coming back next year to complete my research. I’ve applied for grants for two projects: the composition of anti-inflammatory hydrogels for various applications in wound dressing and tissue engineering and the development of anti-inflammatory polymer nanoparticles to enhance osteogenesis. But until now, I’m going to finish my project at the laboratory in Egypt where, together with my colleagues from ITMO, I’m working to produce novel functional materials for our research.